The GMX41 chuck leverages the power of rare earth magnets, which are renowned for their high magnetic strength and stability. These magnets are typically made from neodymium-iron-boron (NdFeB), a material that offers good magnetic properties compared to traditional ferrite magnets. The use of rare earth magnets in the GMX41 allows for a stronger magnetic field, which translates to a more secure grip on the workpiece, reducing the risk of accidents and ensuring the integrity of the machining process.

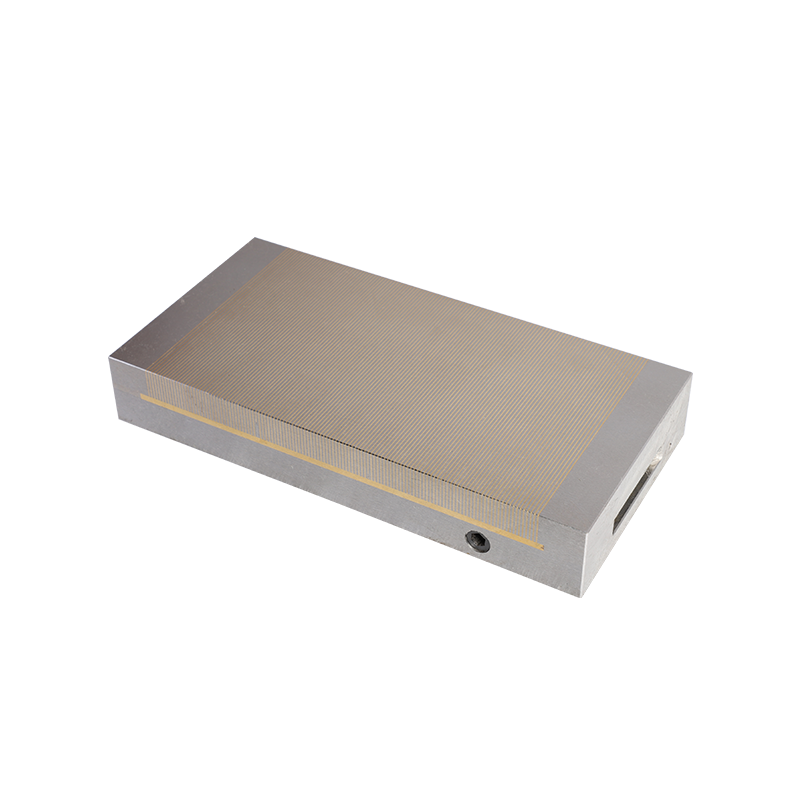

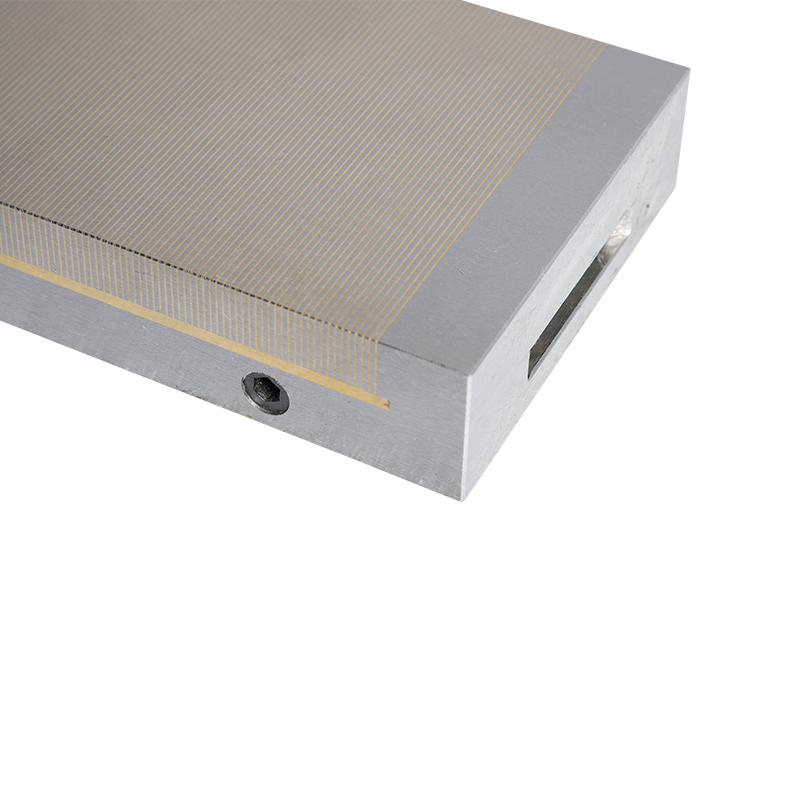

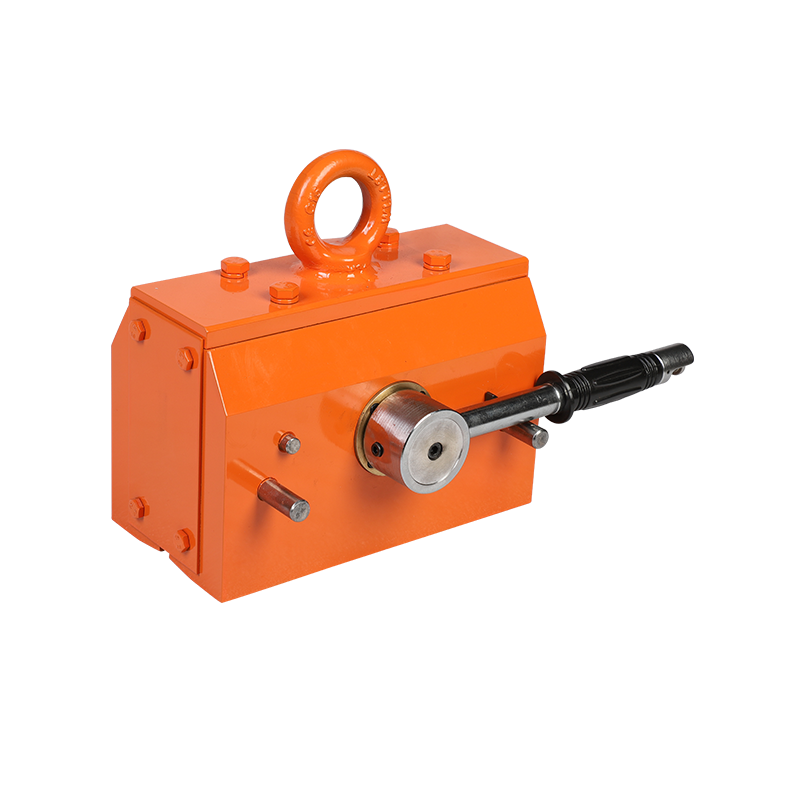

One of the key features of the GMX41 is its design, which is optimized for heavy-duty applications. The chuck's structure is robust, often made from high-grade steel or other durable materials that can withstand the forces exerted during the clamping and unclamping of heavy workpieces. The magnetic circuit within the chuck is carefully engineered to distribute the magnetic flux evenly across the surface, ensuring uniform adsorption force and preventing any potential distortion of the workpiece.

The chuck's magnetic force is generated by the alignment of the magnetic domains within the rare earth magnets. When the magnetic field is activated, these domains align to create a powerful, directed force that attracts and holds the ferromagnetic material. The GMX41 chuck is designed to maintain a constant magnetic force even under varying temperatures and heavy loads, which is crucial for maintaining precision and consistency in the manufacturing process.

The high power rating of the GMX41 chuck means it can handle larger and heavier workpieces than standard models. This is particularly beneficial in industries such as automotive, aerospace, and heavy machinery, where large-scale components are common. The chuck's ability to handle these loads safely and efficiently can significantly reduce production times and increase throughput.

Another important aspect of the GMX41 chuck is its ease of use. The chuck can be quickly and easily attached to a worktable or machine surface, with the magnetic force providing instant clamping once the workpiece is placed on the chuck's surface. This eliminates the need for manual clamping devices, which can be time-consuming and require additional labor. The chuck's permanence also means that once the magnetic field is established, it does not require any additional power or maintenance, reducing operational costs and increasing energy efficiency.

The GMX41 chuck also incorporates safety features to prevent accidental release of the workpiece. Many permanent magnetic chucks, including the GMX41, are designed with a fail-safe mechanism that ensures the workpiece remains securely in place even in the event of a power failure or other unexpected issues. This is achieved through the use of a magnetic circuit breaker or similar device that can detect a loss of magnetic field and trigger an alarm or other safety protocol.

In terms of maintenance, the GMX41 chuck requires minimal upkeep. The rare earth magnets used in the chuck do not degrade over time, and the chuck's sturdy construction means it can withstand the rigors of daily use in an industrial setting. However, it is important to regularly inspect the chuck for any signs of wear or damage, such as cracks or chips in the magnetic plate, which could compromise its performance.

In conclusion, the GMX41 High Power Permanent Magnetic Chuck is a sophisticated piece of equipment that embodies the advancements in magnetic clamping technology. Its high magnetic force, robust design, and user-friendly operation make it an invaluable asset in a variety of industrial applications. By understanding the intricacies of the GMX41 chuck, manufacturers can optimize their production processes and ensure high levels of safety and efficiency in their operations.