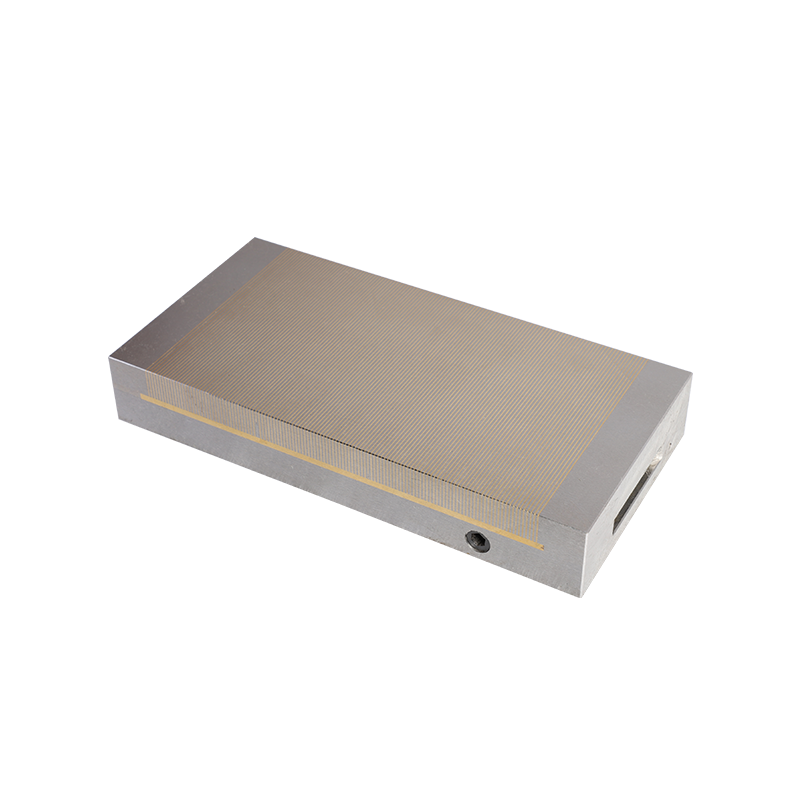

A Dense Permanent Magnetic Chuck is a highly reliable device widely used in machining operations to hold ferromagnetic workpieces securely on milling, grinding, or turning machines. Its dense magnetic structure provides a strong holding force and precision clamping, making it ideal for heavy-duty industrial applications. However, to achieve suitable performance, careful attention must be paid during installation and workpiece preparation. Proper base alignment and surface preparation are essential to ensure magnetic adhesion and prevent unsafe conditions caused by uneven surfaces or improper contact.

Before installing the Dense Permanent Magnetic Chuck, the machine table or base surface must be thoroughly cleaned and inspected. Any dirt, debris, oil, or rust can interfere with magnetic contact and reduce holding force. It is crucial to remove all contaminants using a clean cloth and suitable cleaning agents. Additionally, the base should be checked for flatness and levelness. Even minor warping or irregularities can cause the magnetic chuck to sit unevenly, reducing effective magnetic area and potentially causing the workpiece to shift during machining. Using precision measuring tools such as a dial indicator or surface gauge can help verify the flatness of the mounting surface.

Correct alignment of the Dense Permanent Magnetic Chuck on the machine table is vital for consistent performance. The chuck should be positioned using reference edges or alignment keys, if available, to ensure it is square with the machine axes. Misalignment can result in uneven magnetic force distribution, which may compromise workpiece stability and cause machining errors. Tightening bolts or clamps gradually and in a balanced sequence helps prevent tilting of the chuck while securing it to the table. Proper alignment ensures that the entire surface of the chuck is in firm contact with the base, improving magnetic holding strength.

The workpiece itself must also be prepared for suitable adhesion. The contact surface of the metal should be clean, flat, and free of paint, scale, or oxidation. Irregularities such as burrs or surface roughness can create gaps between the chuck and the workpiece, significantly reducing magnetic force. If necessary, lightly machining or grinding the contact area can improve flatness and ensure full contact with the chuck surface. For cylindrical or irregularly shaped objects, additional supports or clamps may be required to maintain stability during machining. Proper workpiece preparation prevents slipping, tilting, and uneven clamping, enhancing both safety and machining accuracy.

After installation and workpiece placement, it is important to verify the stability of the setup before starting machining operations. Applying a gentle push to test the adhesion or using measuring tools to check workpiece alignment can help detect any potential issues. Dense Permanent Magnetic Chucks often include indicators or mechanical locks that confirm full magnetic engagement, and these should be checked carefully. Ensuring both the base and workpiece are properly prepared reduces the risk of accidents, material damage, and machining errors.

Achieving performance from a Dense Permanent Magnetic Chuck requires careful attention to base surface preparation, precise alignment, and thorough workpiece cleaning. Proper installation ensures full magnetic contact, suitable holding force, and safe machining operations. By following these guidelines, operators can prevent uneven magnetic adhesion, maintain workpiece stability, and extend the lifespan of both the magnetic chuck and the machine tool.