Magnetic chucks are widely used in industrial machining to hold ferromagnetic workpieces securely on milling, grinding, or lathe machines. There are three main types: traditional permanent magnetic chucks, electromagnetic chucks, and Electro Permanent Magnetic Chucks. Each type has unique features, advantages, and limitations that determine its suitability for specific applications. Understanding the differences among these chucks helps manufacturers and operators select the solution for their machining tasks while ensuring safety, efficiency, and cost-effectiveness.

Traditional permanent magnetic chucks rely entirely on the inherent magnetic properties of permanent magnets, such as ferrite or rare-earth materials. They maintain magnetic force without any electricity, making them highly energy-efficient. Because they do not require a power supply, they continue holding workpieces even during power outages, providing a safety advantage. Traditional permanent magnetic chucks are simple in design, lightweight, and require minimal maintenance. However, their main limitation is the inability to adjust the magnetic force. Once manufactured, the holding capacity is fixed, which reduces flexibility for handling workpieces of different sizes or weights. They are also less suitable for precise on-off control compared to other types of magnetic chucks.

Electromagnetic chucks generate a magnetic force by passing an electric current through coils embedded in the device. Their magnetic strength can be easily turned on or off, offering adjustable and precise control. This makes them highly versatile, especially for applications that involve frequent engagement and disengagement of workpieces or where rapid switching is required. Electromagnets are ideal for automated machining systems and high-production environments. However, they require continuous power to maintain magnetic force, increasing energy consumption and operational costs. In the event of a power outage, the workpiece can be released unintentionally, creating safety risks. Additionally, electromagnetic chucks are generally heavier and more complex, requiring regular inspection and maintenance of electrical components to ensure reliability.

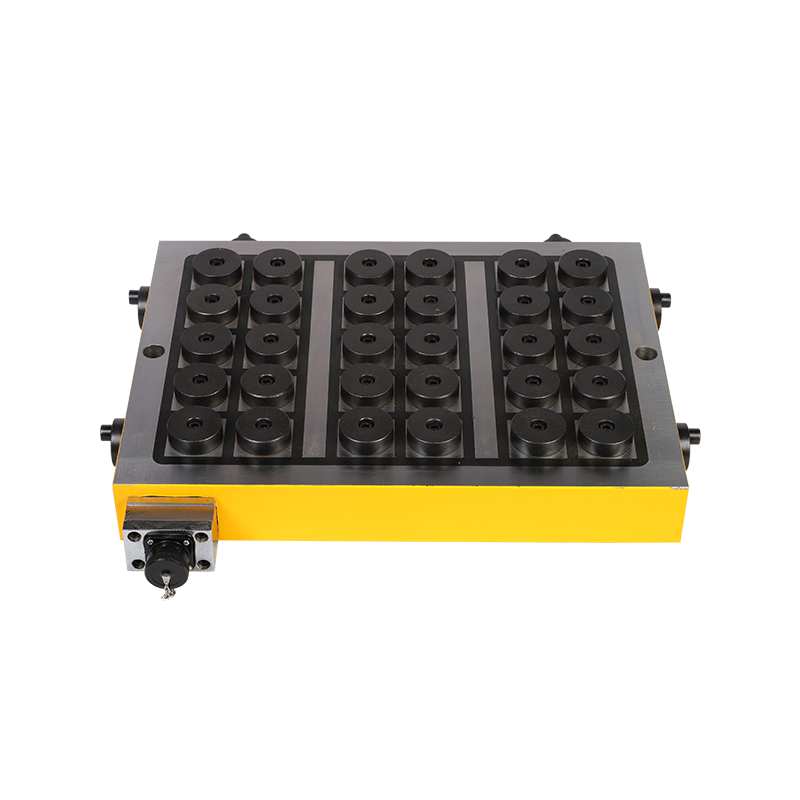

Electro Permanent Magnetic Chucks combine the advantages of both permanent magnets and electromagnets. They use a permanent magnet structure whose magnetic field can be activated or deactivated with a short electrical pulse. Once magnetized, the chuck maintains full magnetic force without continuous power, providing energy efficiency and safety during power loss. This feature allows precise on-off control, similar to an electromagnetic chuck, while maintaining the reliability of a permanent magnet. Electro Permanent Magnetic Chucks are also suitable for lifting, clamping, and precision machining of heavy steel workpieces. Their main drawbacks are a higher initial cost and a slightly more complex design compared to traditional permanent magnetic chucks.

Selecting the appropriate chuck depends on the specific machining requirements. Traditional permanent magnetic chucks are ideal for energy-efficient operations where flexibility is not a primary concern. Electromagnetic chucks excel in dynamic, automated, or high-speed production environments requiring frequent switching. Electro Permanent Magnetic Chucks provide a balanced solution, combining energy efficiency, safety, and adjustable control, making them suitable for precision and heavy-duty applications.

The Electro Permanent Magnetic Chuck offers a hybrid solution that bridges the gap between traditional permanent magnets and electromagnetic chucks. While each type has unique advantages and limitations, understanding these differences allows manufacturers and operators to optimize safety, efficiency, and productivity in their machining processes. Proper selection ensures reliable workpiece clamping, energy savings, and reduced operational risks across various industrial applications.