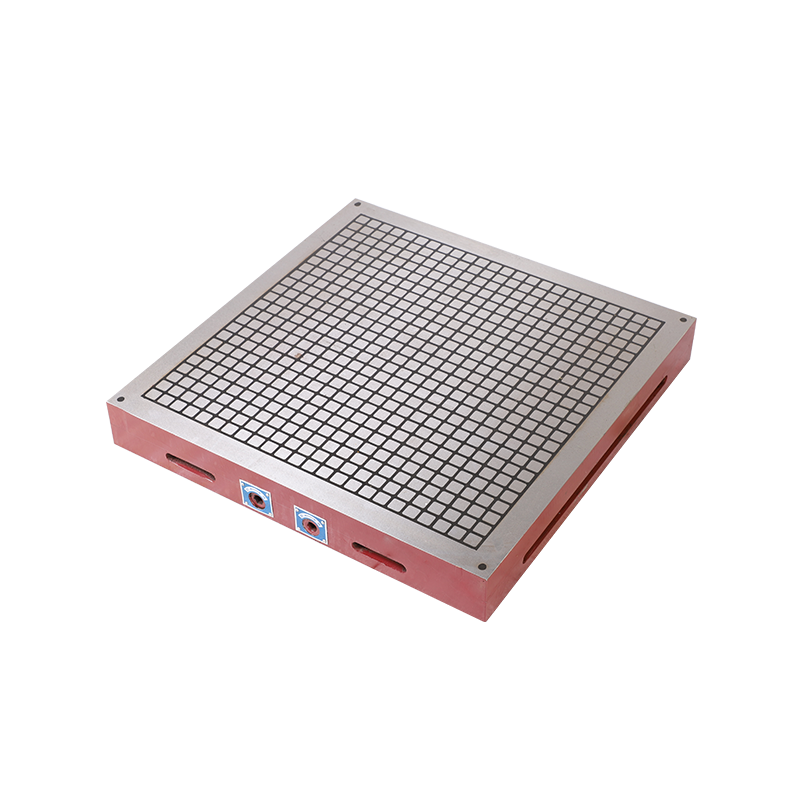

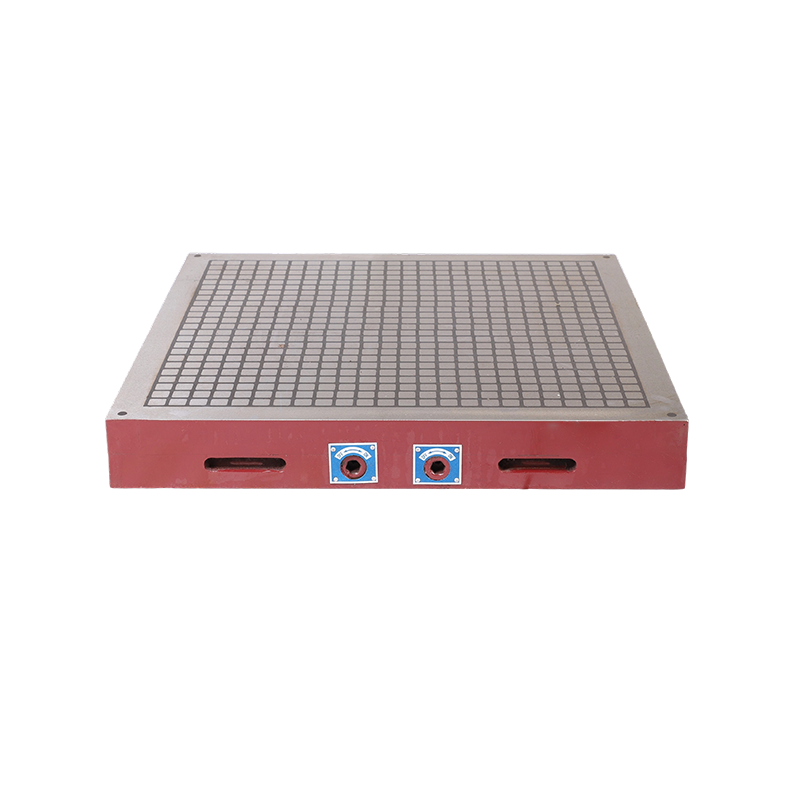

The PMQC Model Strong Permanent Magnetic Chuck is a specialized tool designed for the precision clamping and positioning of ferrous materials in various industrial applications. This chunk is a good example of how magnetic technology can be harnessed to enhance productivity and safety in the workshop.

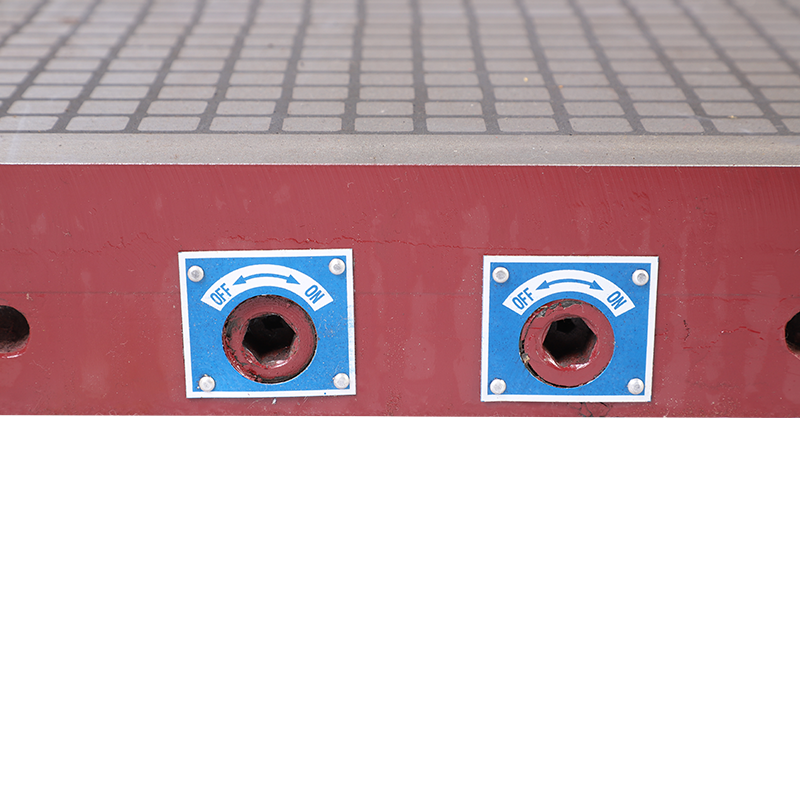

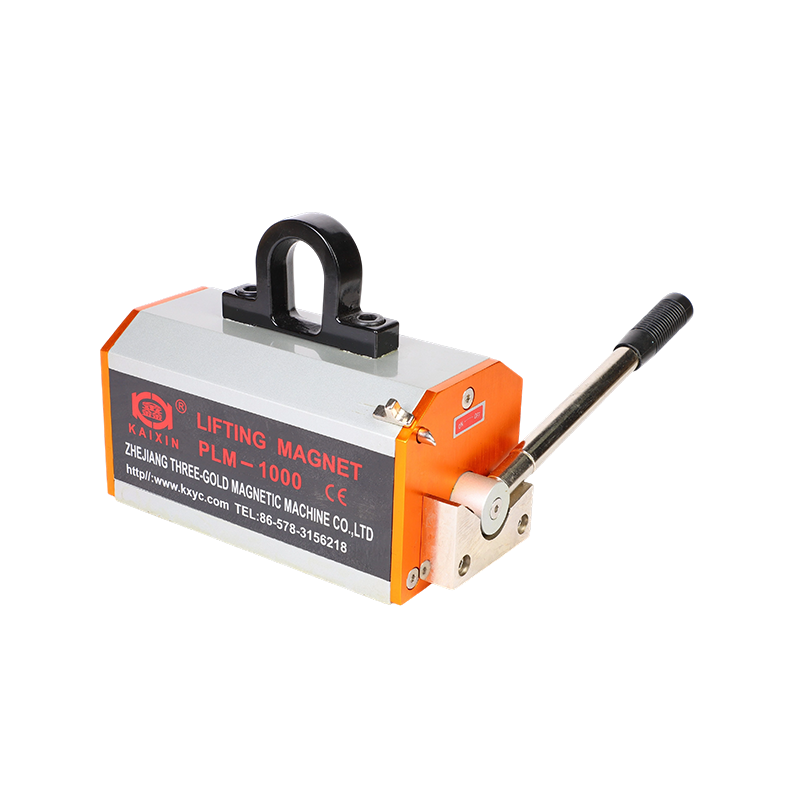

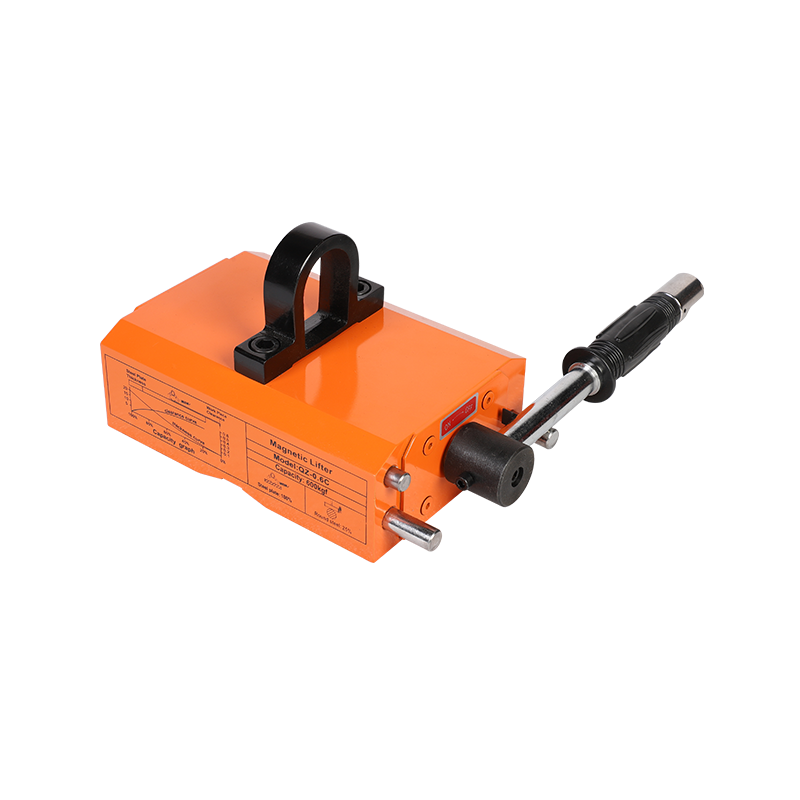

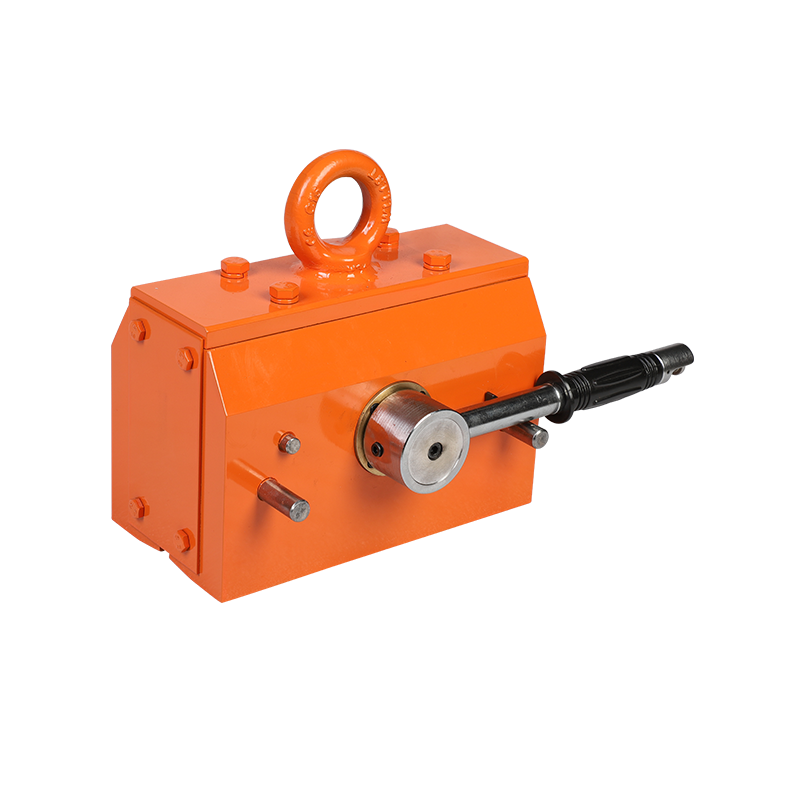

Permanent magnetic chucks, such as the PMQC Model, are renowned for their ability to hold workpieces without an external power supply, which is a significant advantage over electromagnetic chucks that require a continuous power source. This self-contained clamping solution is ideal for applications where power outages could cause workpiece loss or where a clean, power-free workspace is preferred.

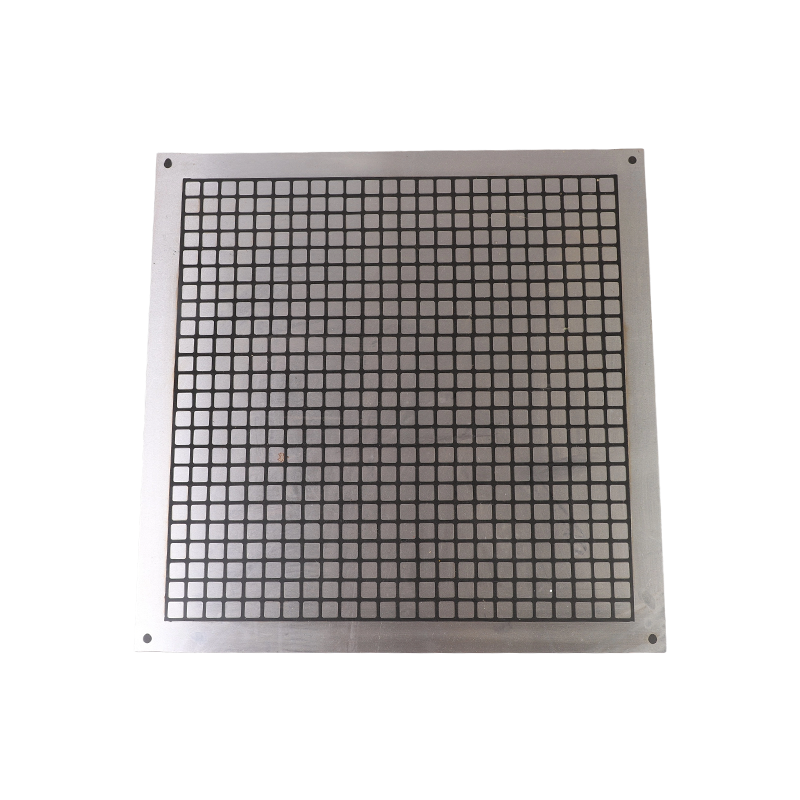

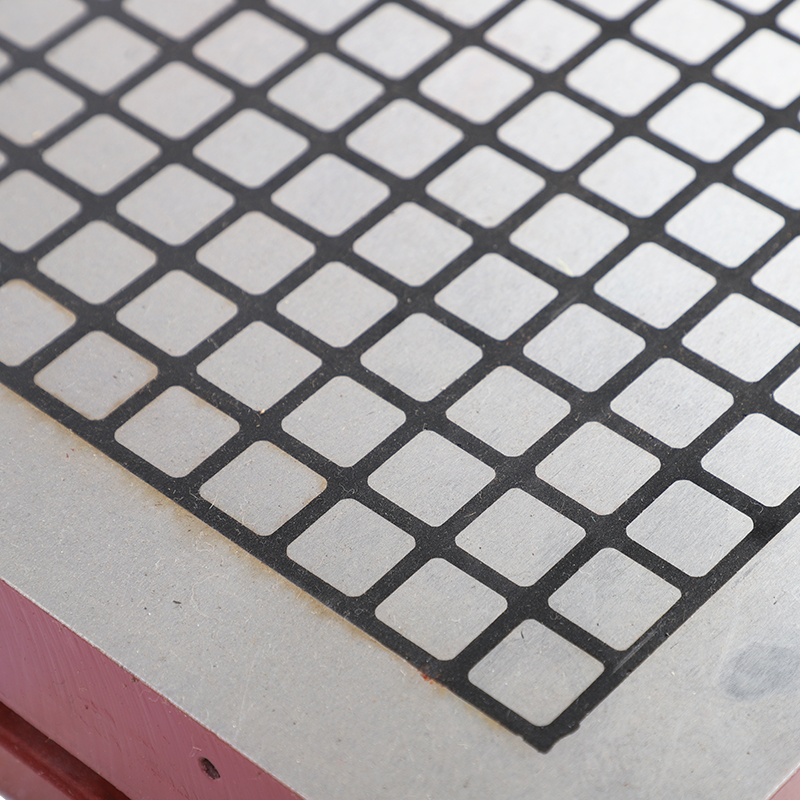

The PMQC Model's construction is typically robust, featuring a magnetic plate made from high-grade magnetic material that ensures a strong and stable magnetic field. The magnetic circuit is designed to distribute the magnetic flux evenly across the work surface, preventing any hot spots that could cause workpiece deformation. The chuck's magnetic strength is adjustable, allowing for a customized clamping force that can be tailored to the specific weight and size of the workpiece.

One of the key features of the PMQC Model is its ability to provide a secure hold on various ferrous materials. This is achieved through the use of a high coercivity magnetic material that resists demagnetization, ensuring the chuck maintains its magnetic properties over time, even under the stress of heavy use. The chuck's magnetic field is also designed to penetrate the workpiece, creating a mechanical interlock that prevents the workpiece from shifting during high-speed or high-vibration operations.

In terms of safety, the PMQC Model includes features such as a manual release mechanism, allowing operators to quickly and safely disengage the magnetic field when the workpiece needs to be removed. This is particularly important in high-pressure environments where quick changeovers are necessary. Additionally, the chuck is often equipped with safety features to prevent accidental demagnetization, such as protective covers or shields that prevent external factors from affecting the magnetic field.

Maintenance of the PMQC Model is minimal due to the lack of moving parts and the absence of an electric current, which reduces the risk of electrical faults. However, it is still important to regularly inspect the chuck for any signs of wear or damage, particularly the magnetic surface, which can be affected by chipping or excessive heat.

The PMQC Model's versatility is evident in its ability to accommodate a wide range of workpiece sizes and shapes. The chuck's flat surface can be adapted to fit various jigs and fixtures, and its magnetic force can be distributed evenly across the entire surface, making it suitable for large, heavy workpieces that require a uniform clamping force.

In the context of precision machining, the PMQC Model's consistent and reliable hold is crucial. It ensures that workpieces remain in position throughout the machining process, reducing the risk of inaccuracies and scrap. This is particularly important in industries such as aerospace, automotive, and heavy machinery manufacturing, where high tolerances and exacting standards are the norm.

The PMQC Model's efficiency is also noteworthy. By eliminating the need for manual clamping and unclamping, it can significantly reduce setup times and increase throughput. This is especially beneficial in high-volume production environments where every second counts.

In conclusion, the PMQC Model Strong Permanent Magnetic Chuck is a powerful and versatile tool that enhances the efficiency, safety, and precision of ferrous material handling in industrial settings. Its design, featuring a strong and stable magnetic field, adjustable clamping force, and minimal maintenance requirements, makes it an invaluable asset in the modern workshop.