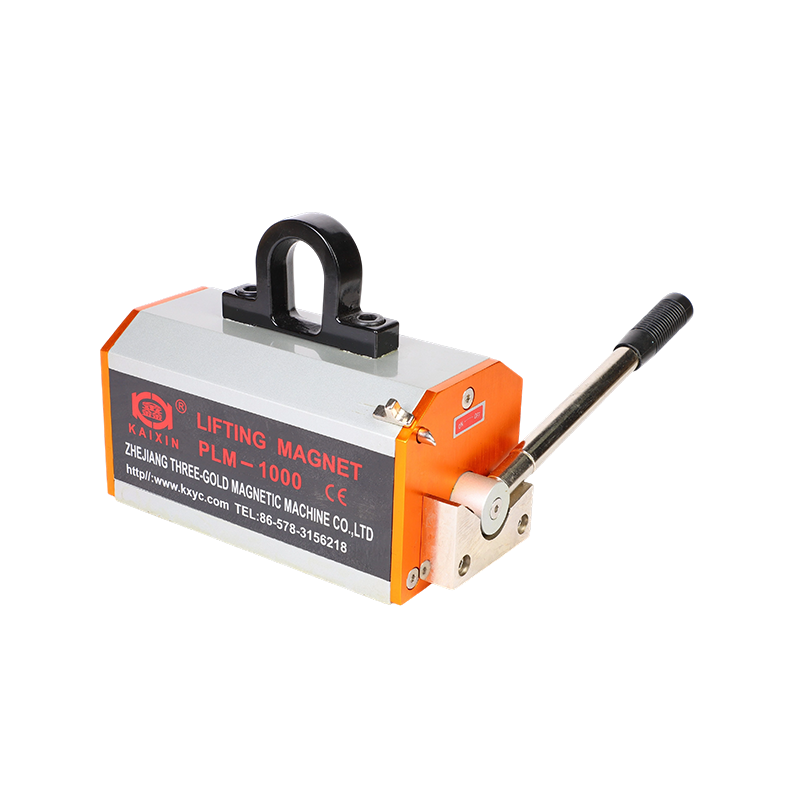

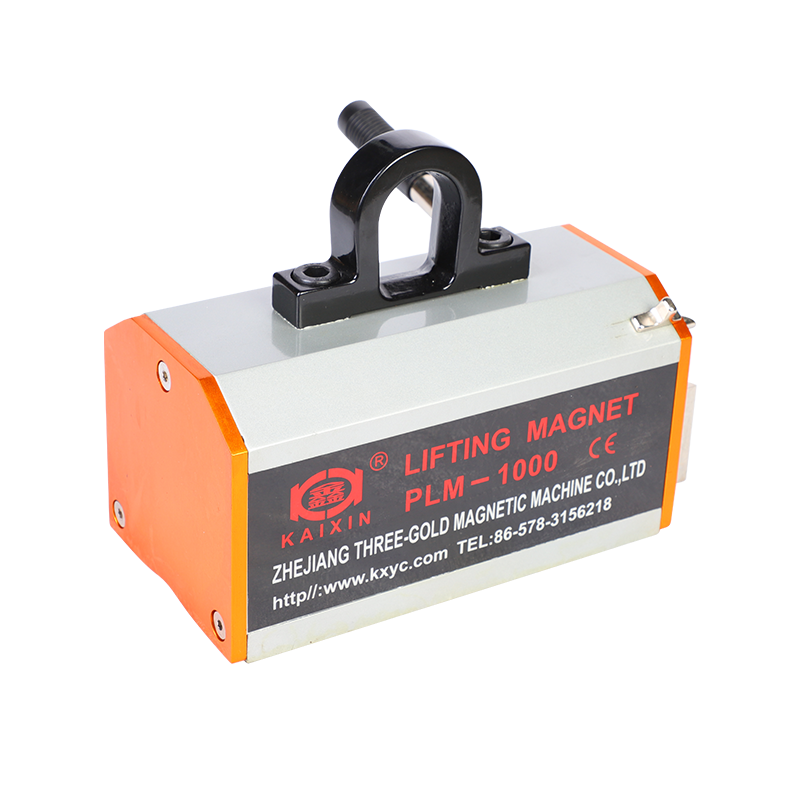

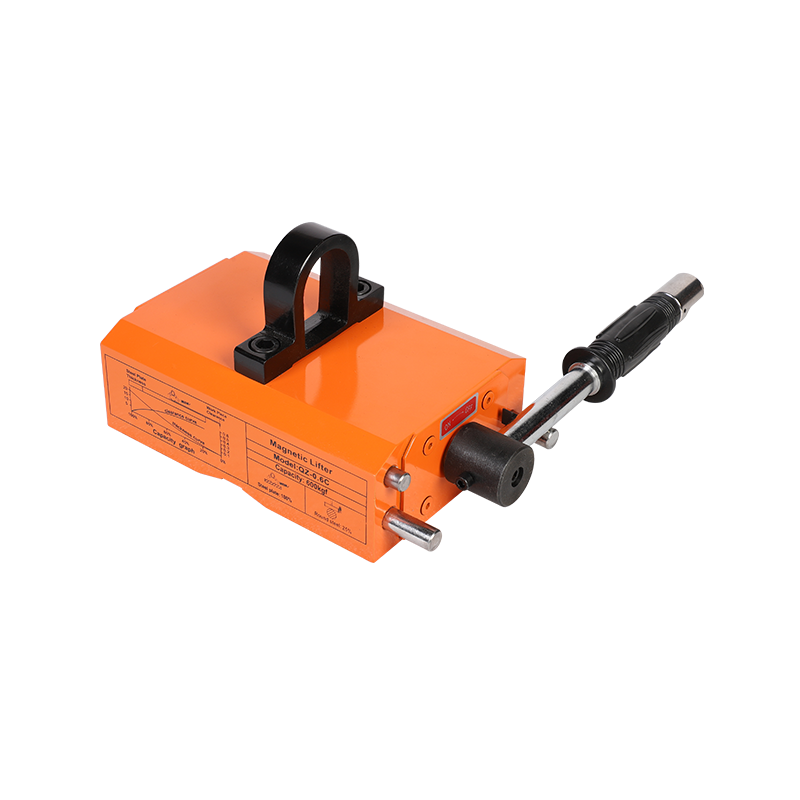

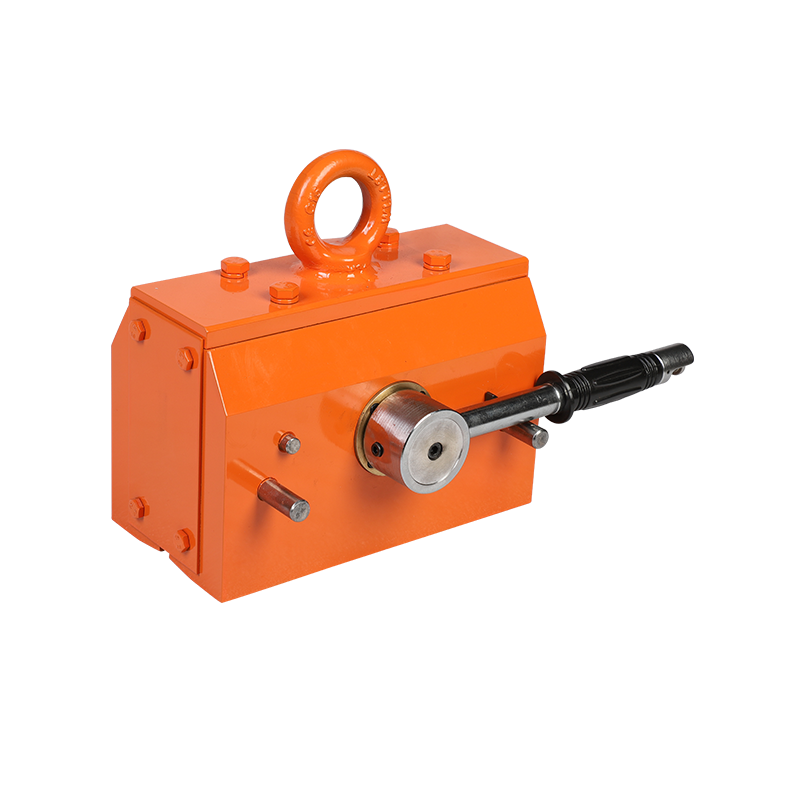

The PML model is a crane permanent magnet lifter that is designed to handle heavy steel plates and other ferromagnetic materials with ease. It is a good choice for industries where precision and safety are paramount, such as shipbuilding, heavy machinery manufacturing, and steel processing. The lifter's magnetic force is generated by rare earth magnets, which are known for their high magnetic strength and durability. This ensures that the PML model can securely hold and lift heavy loads without the need for electricity, making it an energy-efficient and reliable solution.

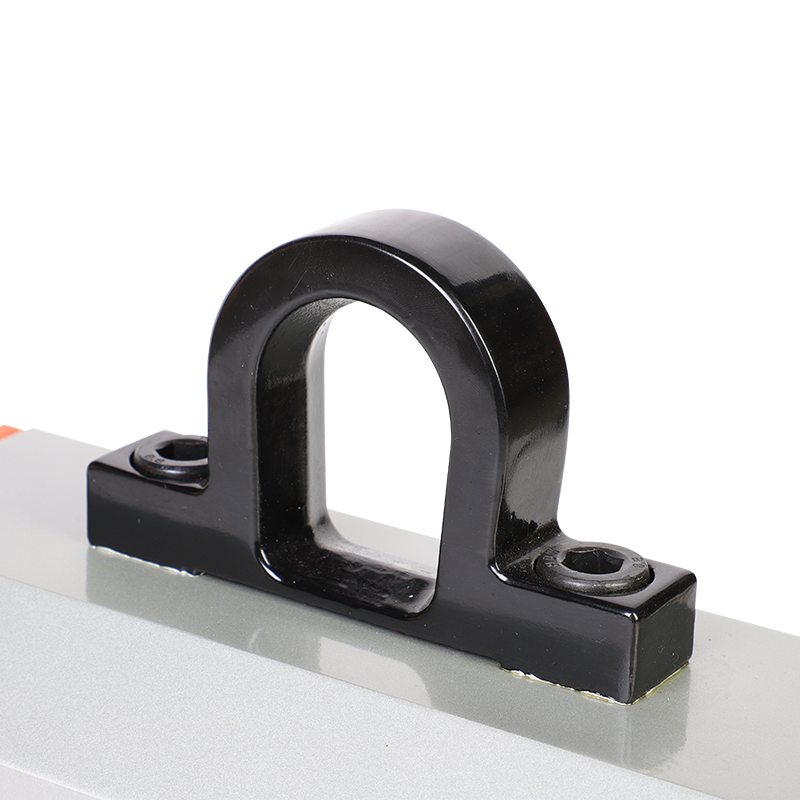

One of the key features of the PML model is its safety release mechanism. This patented system allows for the controlled release of the load, which is crucial in preventing accidents and ensuring the safety of workers in the vicinity. The release mechanism is designed to be fail-safe, meaning that in the event of a loss of control, the lifter will not accidentally drop the load, thus reducing the risk of injury and damage to equipment.

Our PML model is also designed with versatility in mind. It can be easily attached to cranes or other lifting mechanisms, making it compatible with a wide range of existing equipment. This adaptability allows our customers to integrate the PML model into their current workflow without the need for significant modifications or additional investments.

The lifter's magnetic force is adjustable, which means that it can be tailored to the specific weight and size of the materials being handled. This feature is particularly useful in environments where a variety of different materials are being processed, as it allows for greater flexibility and efficiency in the handling process.

In terms of maintenance, the PML model is relatively low-maintenance, thanks to its robust construction and the use of high-quality materials. The rare earth magnets used in the lifter are resistant to demagnetization, which means that they maintain their magnetic strength over time, even under heavy use. This reduces the need for frequent repairs or replacements, saving our customers both time and money.

We also understand the importance of ease of use, which is why the PML model is designed with user-friendly controls. The lifter's operation is intuitive, ensuring that workers can quickly and easily control the lifting and releasing of loads. This reduces the learning curve and allows for faster integration into existing workflows.

In addition to the PML model, we also offer a range of vacuum suction cups, which are ideal for lifting non-ferromagnetic materials such as glass, ceramics, and certain types of metal. These suction cups are designed to provide a strong and secure grip on smooth, non-porous surfaces, making them a versatile addition to any material handling operation.

Our vacuum suction cups are made from high-quality materials that are resistant to wear and tear, ensuring a long lifespan and reliable performance. They are also easy to clean and maintain, reducing downtime and ensuring consistent performance.

In conclusion, as a manufacturer, we are committed to providing our customers with the advanced and reliable lifting solutions available. Our PML model of permanent magnetic lifter and our vacuum suction cups are a testament to this commitment, offering safety, efficiency, and versatility in a range of industrial applications. We continuously strive to improve our products, incorporating the technology and customer feedback to ensure that we remain at the forefront of the material handling industry.