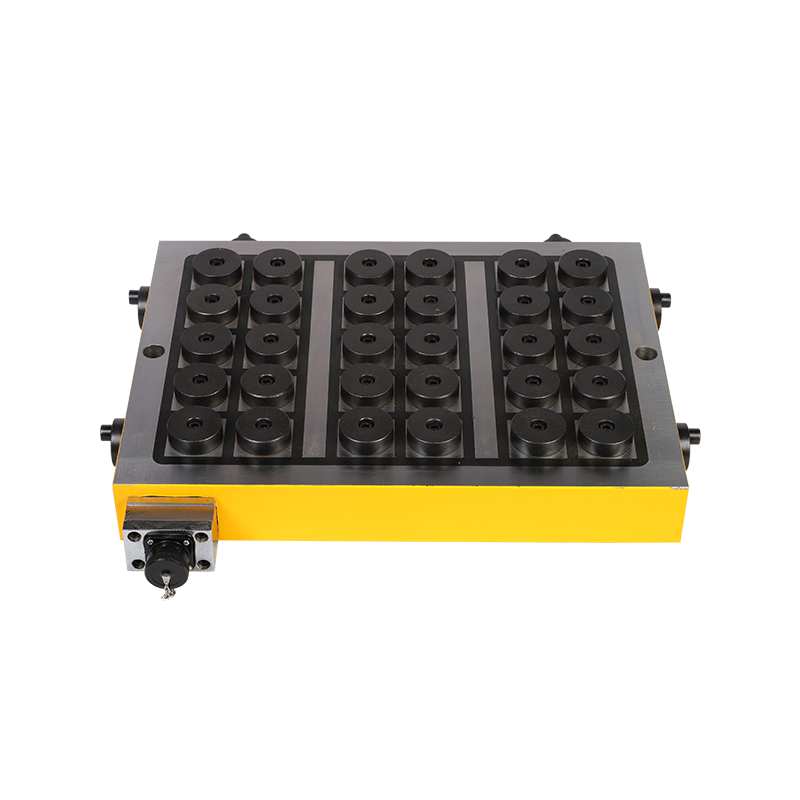

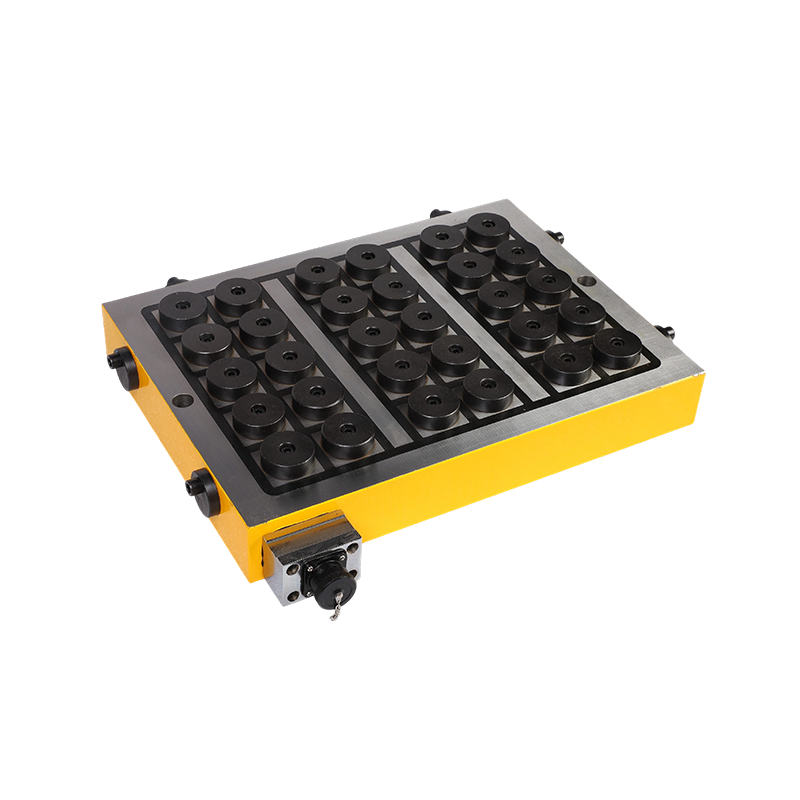

The ECPM type Electric Controlled Permanent Magnetic Chuck is engineered to provide a strong and consistent magnetic hold on ferrous workpieces, with the added benefit of electric control for the activation and deactivation of the magnetic field.

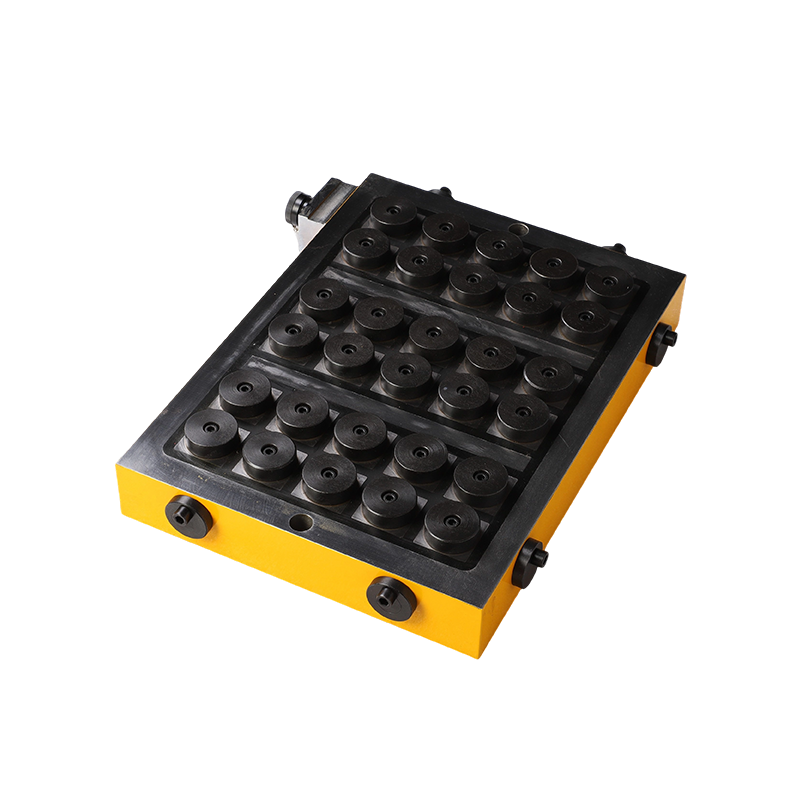

The chuck's design incorporates a matrix of permanent magnets arranged in a pattern that ensures an even distribution of magnetic force across the work surface. The magnetic field is generated by the alignment of these magnets, which creates a powerful attraction to any ferrous metal placed on the chuck. The advantage of permanent magnets is that they do not require a continuous power supply to maintain the magnetic field, which contrasts with electromagnetic chucks that need a constant power source to function.

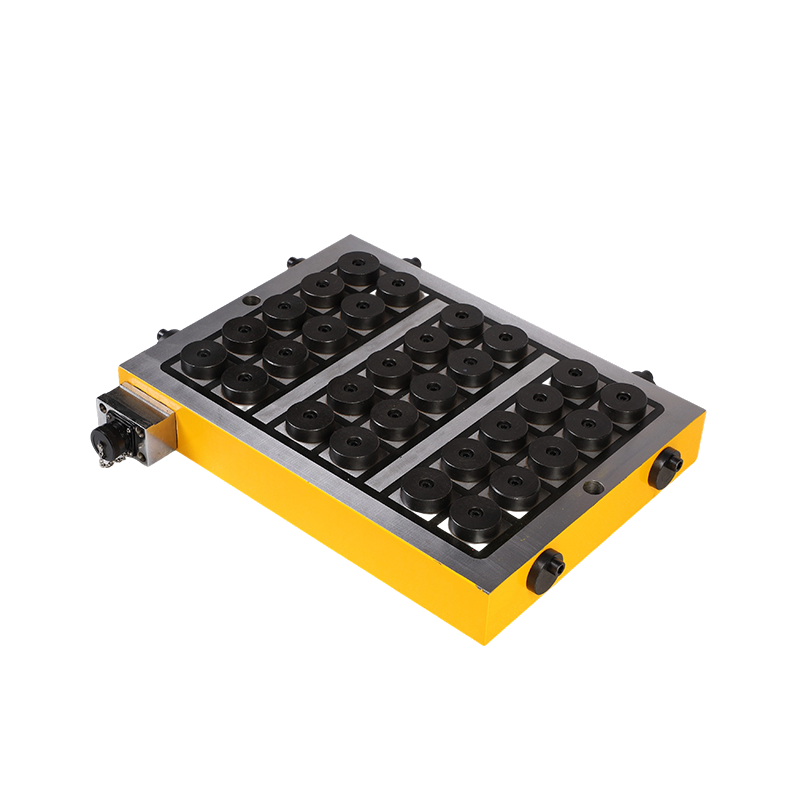

The electric control aspect of the ECPM chuck adds an extra layer of safety and convenience. An electric pulse is used to switch the magnetic field on and off, which means that the chuck can be quickly and easily activated or deactivated as needed. This feature is crucial in scenarios where quick workpiece changes are required, or in environments where the magnetic field could pose a risk if left active unintentionally.

The chuck is designed with a robust construction to withstand the rigors of heavy-duty machining. It is typically made from high-grade materials that can resist wear and tear, ensuring longevity and reliability over time. The surface of the chuck may be treated or coated to prevent rust and corrosion, which is essential in maintaining the integrity of the magnetic field and the overall performance of the chuck.

In terms of performance, the ECPM chuck offers high magnetic flux density, which translates to a strong holding force that can securely hold workpieces in place during cutting, grinding, or other machining processes. This is particularly important in precision machining, where any movement of the workpiece could cause inaccuracies or scrap.

Safety is also a critical consideration in the design of the ECPM chuck. The chuck is equipped with safety features such as an emergency release mechanism that can disengage the magnetic field in case of a power failure or other emergencies. This ensures that the workpiece does not become a flying hazard in the event of a system failure.

The chuck is also compatible with a wide range of workpiece sizes and shapes, thanks to its flexible design. It can be customized to fit specific machine tools or adapted to handle different types of workpieces, making it a versatile tool in any workshop or fabrication facility.

Maintenance of the ECPM chuck is relatively straightforward. While the permanent magnets do not degrade over time like electromagnets, it is still important to keep the chuck clean and free from debris that could interfere with the magnetic field or cause damage to the work surface.

The ECPM type Electric Controlled Permanent Magnetic Chuck is a sophisticated tool that bridges the gap between traditional magnetic and electromagnetic chucks. It offers the strength and reliability of permanent magnets with the controllability and safety features of an electric system, making it an ideal choice for a wide range of metalworking applications where precision, safety, and efficiency are essential.