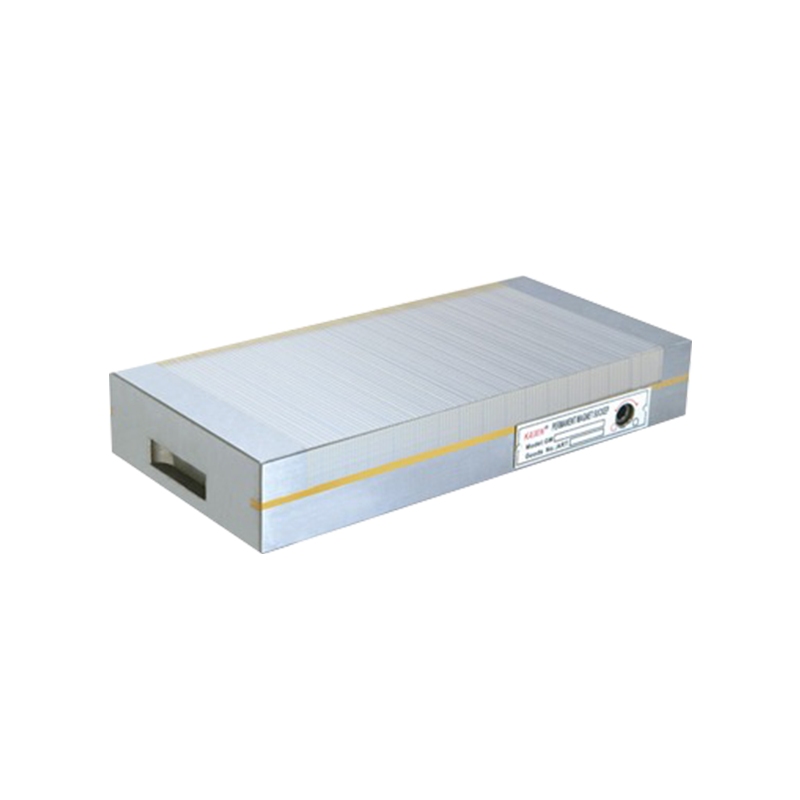

The GMX41 Industrial Permanent Magnetic Chuck, as detailed on the product page, is a specialized tool designed for the metalworking and heavy machinery industry. It stands out for its ability to securely hold ferrous materials during various processes such as cutting, grinding, and drilling, which is crucial for maintaining precision and efficiency in manufacturing operations.

This permanent magnetic chuck is built with a robust structure that ensures durability and longevity even under heavy industrial use. Its construction typically involves a combination of high-grade magnetic materials and a strong steel plate that serves as the base. The magnetic field is generated by the arrangement of permanent magnets within the chuck, which provide a uniform and powerful adsorption force across the entire surface. This uniformity is important as it prevents any distortion of the workpiece, which could cause inaccuracies in the final product.

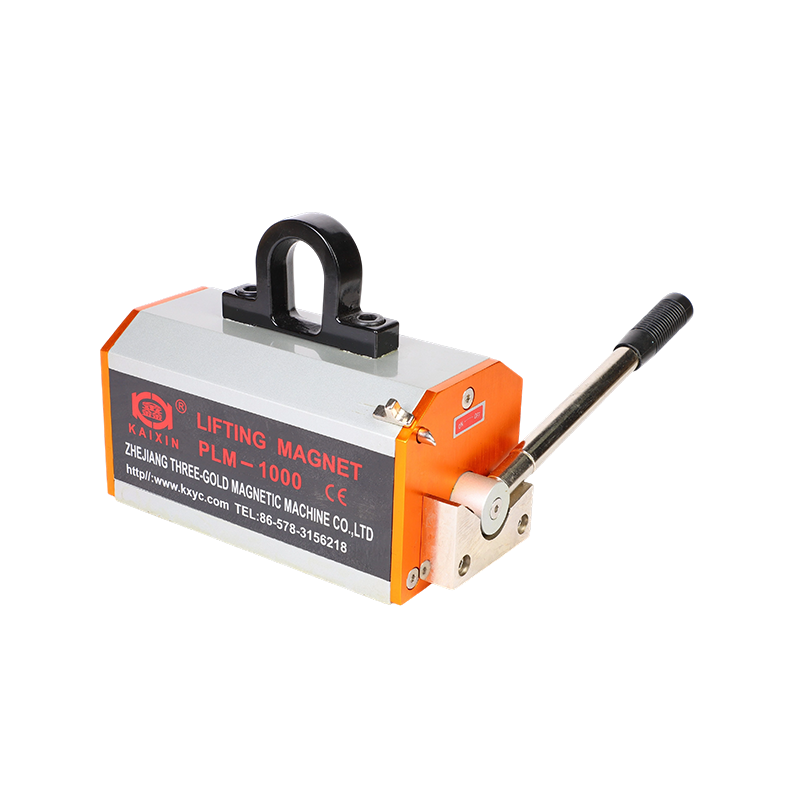

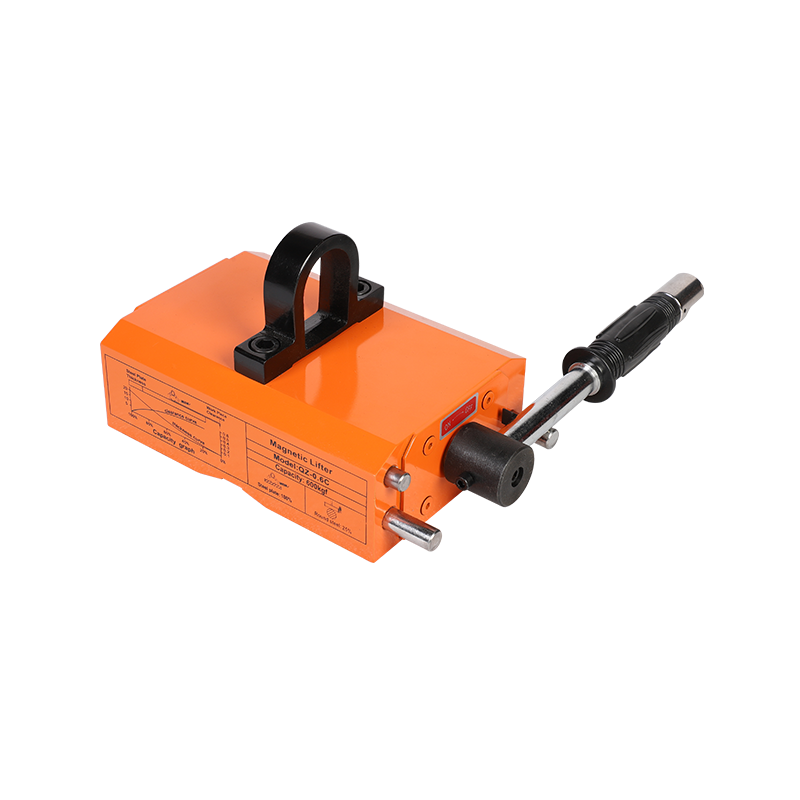

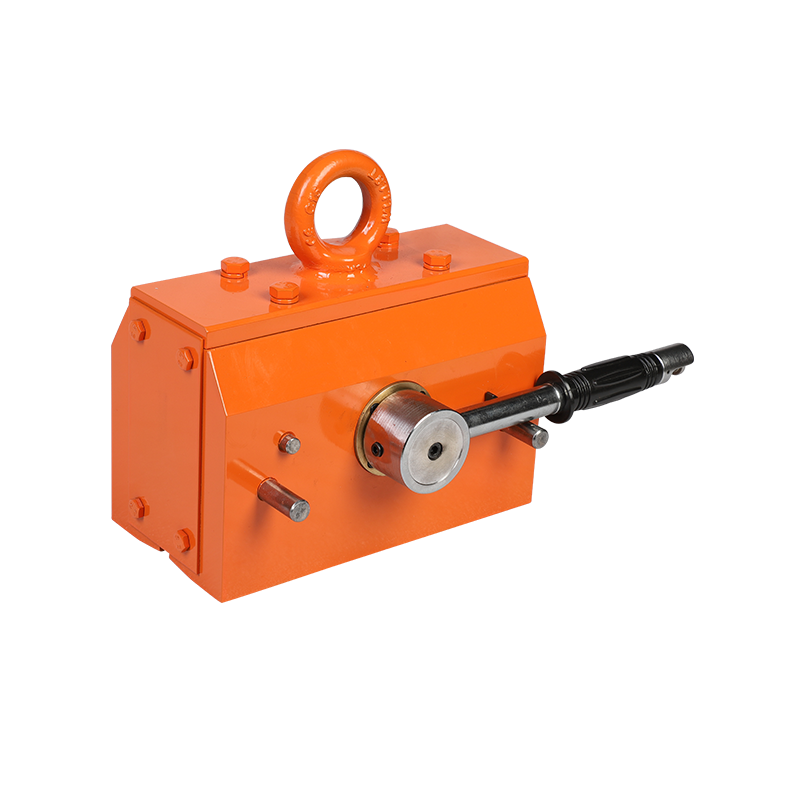

One of the key features of the GMX41 is its ability to maintain a strong grip on the workpiece without the need for an external power source. This is a significant advantage over electromagnetic chucks, which require continuous power to maintain their magnetic field. The absence of power dependency not only reduces operational costs but also reduces the risk of workpiece loss due to power failures, a common concern in environments where power outages can occur.

The magnetic chuck is designed with a flat surface that allows for easy placement and secure holding of workpieces. The flatness is crucial for maintaining the accuracy of the machining process, as any unevenness could cause misalignments. The surface of the GMX41 is also treated to resist wear and corrosion, which is essential for maintaining its performance over time, especially in environments where metalworking fluids are used.

The chuck's operation is straightforward, with a simple mechanism to turn the magnetic field on and off. This is often achieved through a toggle switch or a foot pedal, depending on the specific model and setup. The ease of operation is a critical factor in increasing productivity, as it allows operators to quickly and safely change workpieces without complicated procedures.

In terms of safety, the GMX41 is equipped with features that prevent the accidental release of the workpiece. This includes a safety mechanism that ensures the magnetic field remains active even in the event of a power failure, protecting against workpiece drop and potential damage to both the workpiece and the machinery. Additionally, the chuck is designed to dissipate heat effectively, preventing overheating that could cause magnet demagnetization or damage to the workpiece.

The GMX41's magnetic force is adjustable, which is a valuable feature for handling workpieces of varying thicknesses and materials. This adjustability allows for customization of the clamping force to suit the specific requirements of the job, ensuring suitable holding power without causing damage to the workpiece due to excessive force.

Maintenance of the GMX41 is relatively simple, as permanent magnetic chucks do not have the same wear and tear issues as their electromagnetic counterparts. However, regular inspections are recommended to ensure that the chuck remains in good working order. This includes checking for any signs of surface wear, magnet degradation, and ensuring that the safety mechanisms are functioning correctly.

The GMX41 Industrial Permanent Magnetic Chuck is a high-performance tool that offers a reliable and cost-effective solution for holding ferrous materials in various metalworking applications. Its design, safety features, and ease of use make it an indispensable piece of equipment in any workshop or factory that requires precision and efficiency in its operations.