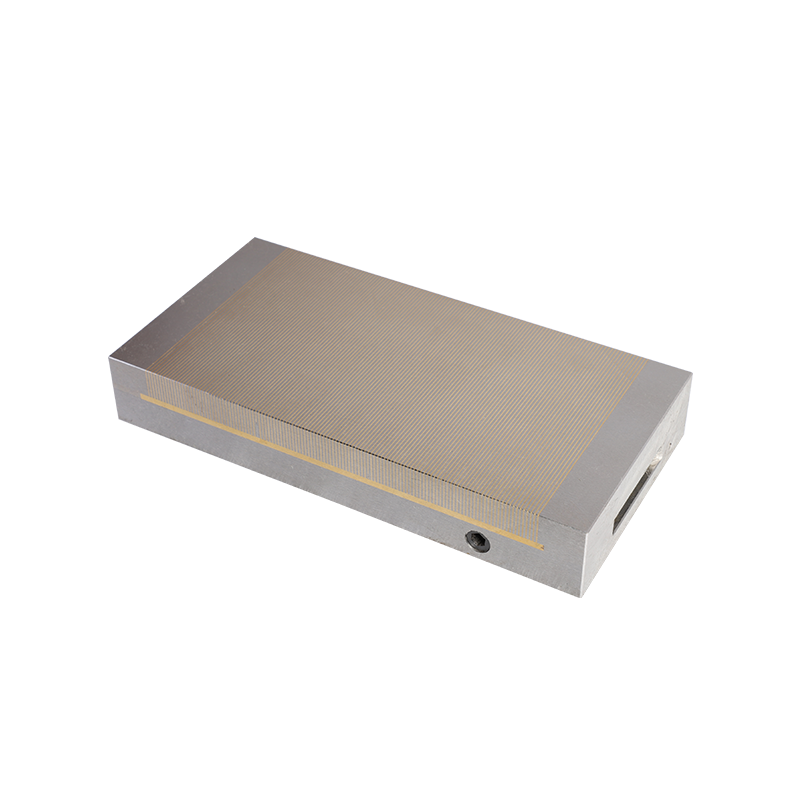

They are used extensively in applications such as sheet metal holding, plate positioning, and the clamping of steel or iron workpieces during cutting, milling, drilling, and grinding operations. These chucks leverage the power of permanent magnets to create a strong, reliable hold on ferrous materials without the need for an external power source once the magnetic field is established.

The product featured on the page is designed with a focus on both performance and safety. It embodies the advancements in magnetic clamping technology, ensuring that it can meet the demands of precision manufacturing processes. The chucks are built with rare earth magnets, which are known for their high magnetic strength and resistance to demagnetization. This allows for a secure grip on workpieces, even under heavy loads or in high-stress environments.

One of the key features of these chucks is their ability to maintain a constant holding force without the need for continuous energy input. This is particularly beneficial in environments where power outages could cause catastrophic failures or where energy efficiency is a priority. The permanent magnets used in these chucks do not lose their magnetism over time, providing a long-term solution for clamping needs.

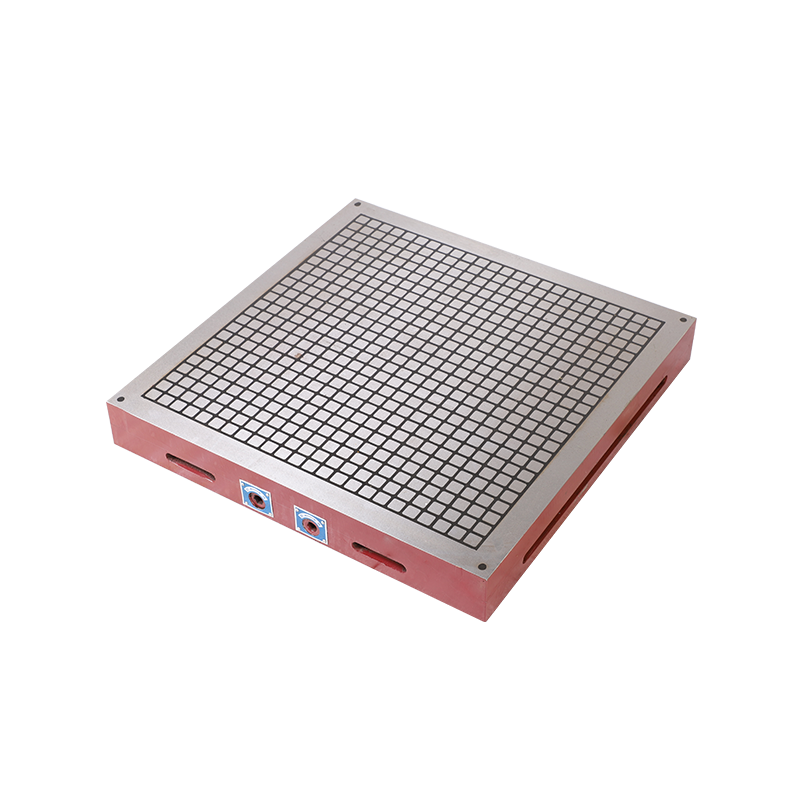

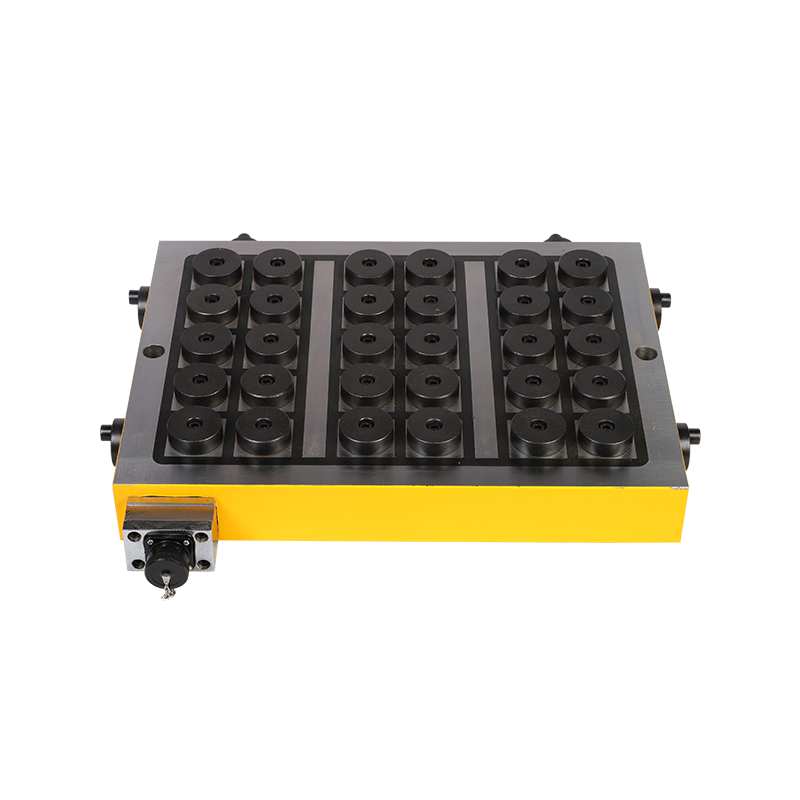

The construction of these chucks often includes a precision-ground base surface that ensures a flat and level contact with the machine table or work surface. This is crucial for maintaining the accuracy and stability of the workpiece during the machining process. Additionally, the chucks may be equipped with a safety mechanism to prevent accidental release of the workpiece, further enhancing safety in the workplace.

In terms of functionality, permanent magnetic chucks can be adapted to various machine tools such as milling machines, drilling machines, and grinding machines. They are particularly useful in applications where a strong, secure hold is required without the need for complex mechanical clamping systems. The chucks can also be designed for specific applications, such as the use of different pole configurations to accommodate various workpiece shapes and sizes.

Maintenance of these chucks is relatively straightforward, as they do not require electrical components that could fail or need regular replacement. However, it is important to keep the chuck clean and free from debris, as this can interfere with the magnetic field and reduce the effectiveness of the clamping force. Regular inspection for signs of wear or damage is also recommended to ensure the continued safe operation of the chuck.

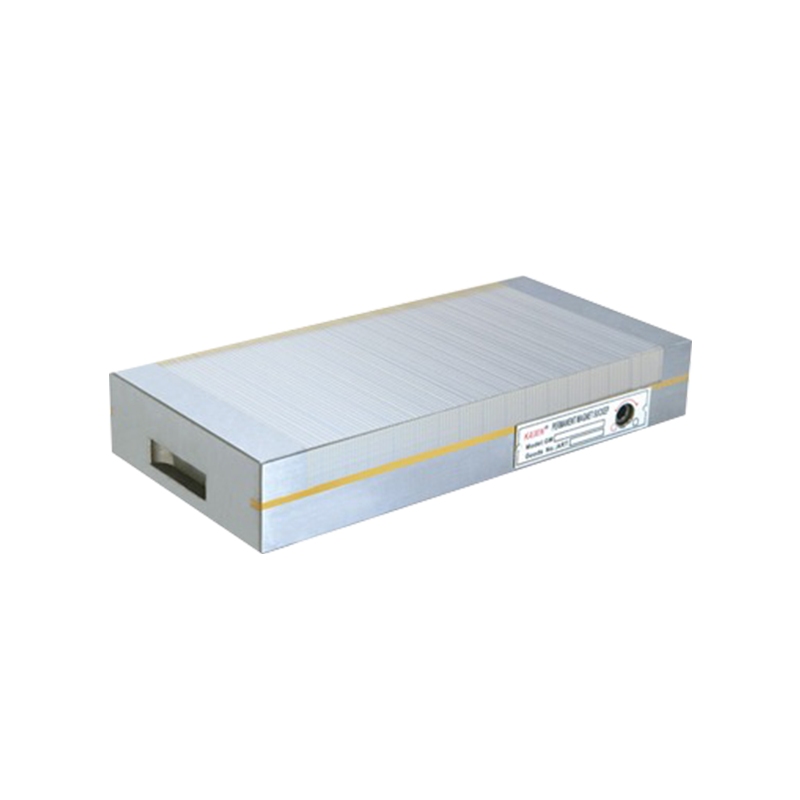

The use of permanent magnetic chucks in the industry has several advantages over traditional clamping methods. They reduce setup time, as there is no need to manually tighten or loosen clamps. They also reduce the risk of operator error, as the magnetic force is consistent and does not require adjustment once the initial setup is complete. This consistency also contributes to improved workpiece quality, as the chuck provides a uniform holding force across the entire surface.

Permanent magnetic chucks are a valuable asset in the metalworking industry. They offer a reliable, efficient, and safe method for holding ferrous materials in place during various machining operations. Their design and construction cater to the needs of precision manufacturing, ensuring that workpieces are held securely and accurately throughout the production process. With proper use and maintenance, these chucks can provide years of dependable service, making them a worthwhile investment for any workshop or manufacturing facility.