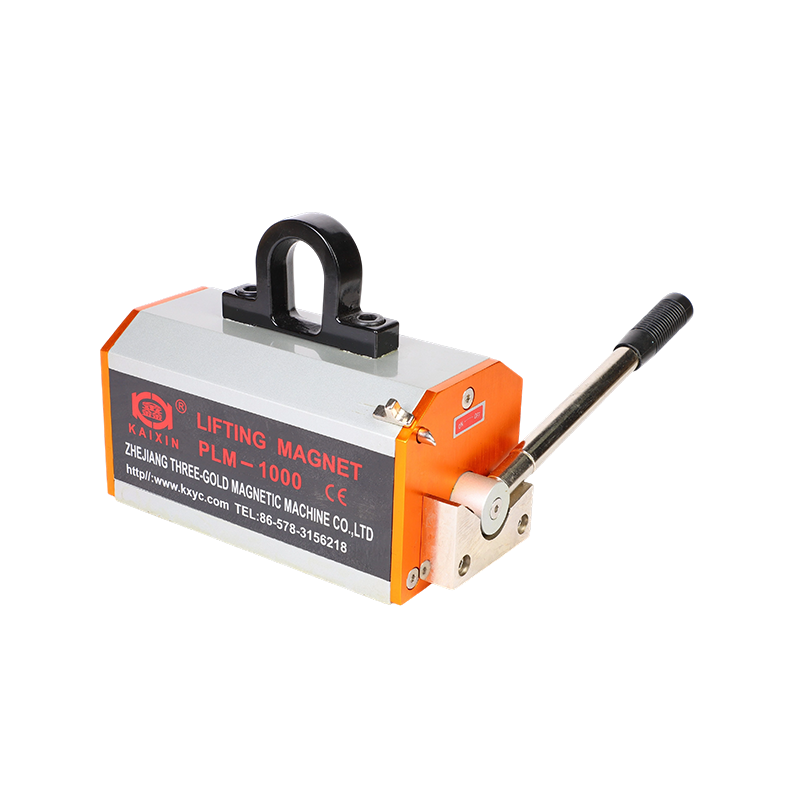

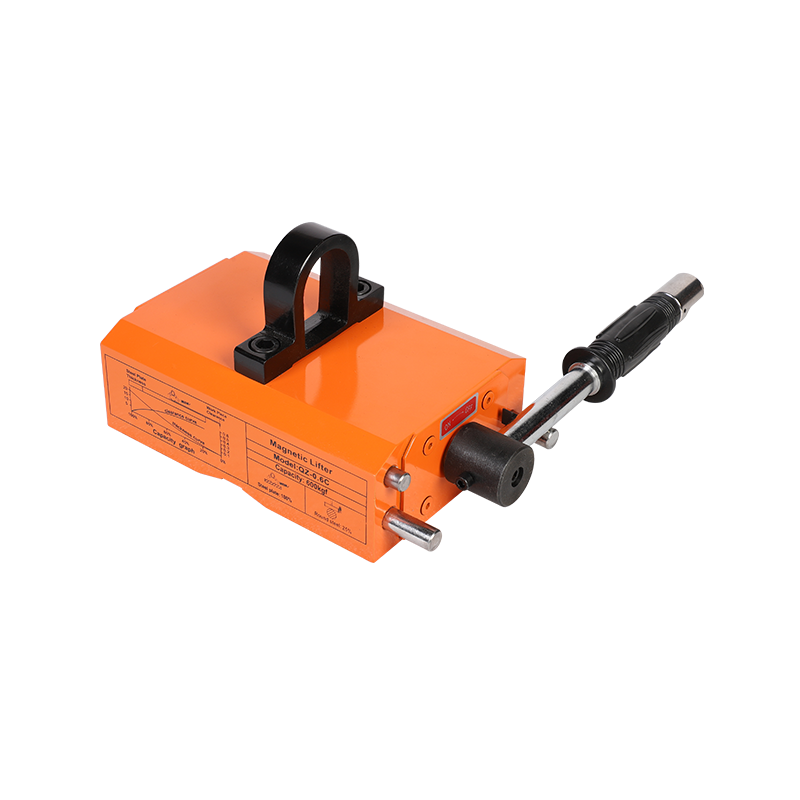

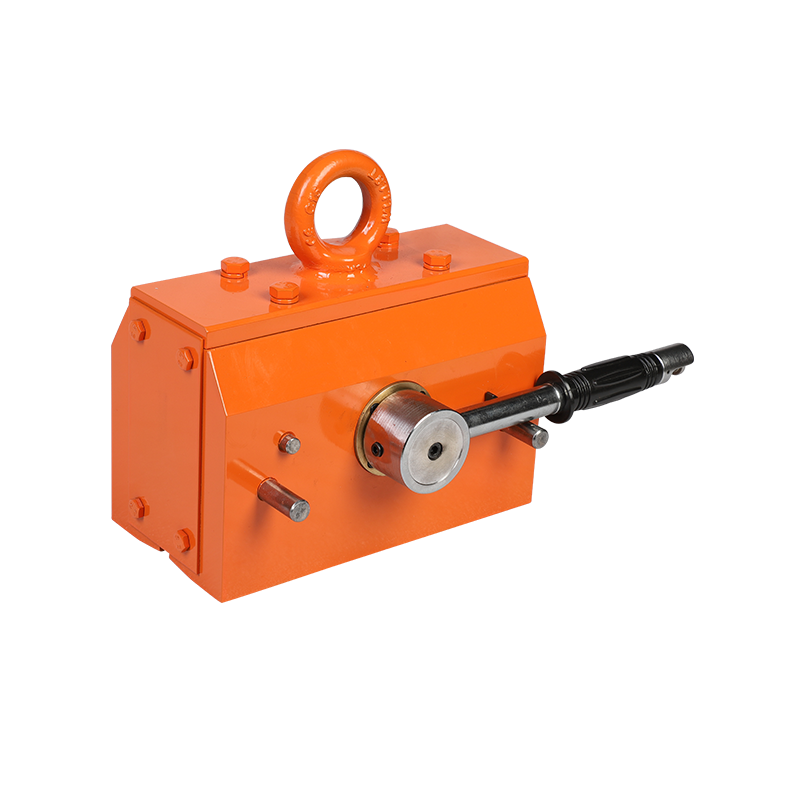

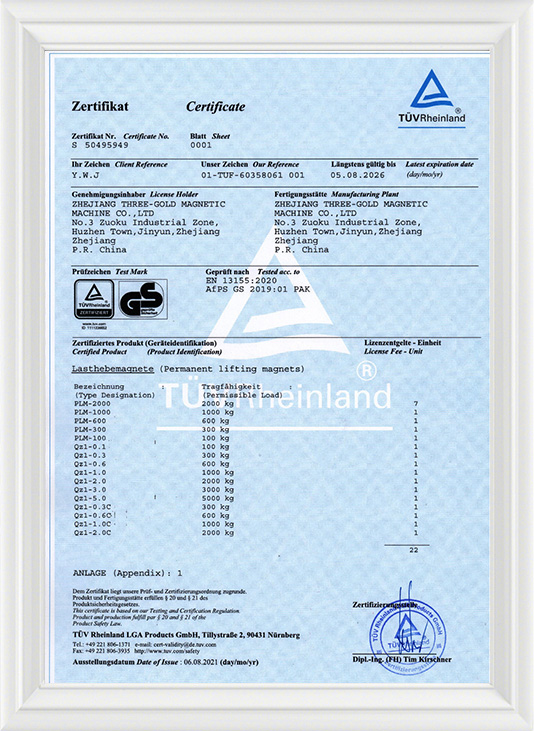

The PMQC Industrial Strong Permanent Magnetic Chuck is a high-performing device designed for the metalworking industry, specifically engineered to handle heavy-duty applications where secure and precise holding of metal workpieces is critical. This chunk is famous due to its robust construction and the use of advanced magnetic materials, which together provide a good level of magnetic holding power.

At the core of the PMQC's functionality lies its permanent magnets, which are strategically arranged within the chuck's structure to generate a strong and uniform magnetic field across the entire contact surface. This uniformity is essential for ensuring that the workpiece is held securely without any risk of slipping or movement, which could cause inaccuracies in the machining process or even damage to the workpiece and machinery.

The use of rare earth magnets in the PMQC is a significant factor in its performance. Rare earth magnets, such as neodymium, are known for their high magnetic strength and resistance to demagnetization. This makes them ideal for industrial applications where high magnetic force is required over a long period without loss of performance. Moreover, the magnetic field generated by these magnets is not affected by temperature fluctuations, ensuring consistent performance even in variable environmental conditions.

One of the key features of the PMQC Industrial Strong Permanent Magnetic Chuck is its ability to hold workpieces without the need for an external power source. This is particularly beneficial in environments where electrical power may be unreliable or where the risk of electrical interference could compromise the safety and integrity of the machining process. The absence of an external power requirement also contributes to the overall energy efficiency of the chuck, reducing operational costs and environmental impact.

In terms of safety and ease of use, the PMQC is designed with a quick-release mechanism that allows for the easy detachment of the workpiece once the machining process is complete. This feature not only speeds up the workflow but also reduces the risk of injury associated with the manual handling of heavy metal workpieces.

The chuck's design also incorporates a wear-resistant surface treatment, which is crucial for maintaining its performance and longevity in tough industrial environments. This treatment helps to protect the chuck from the effects of wear and tear, chemical exposure, and heat, ensuring that it remains functional and effective even after extended periods of use.

The PMQC's ability to hold a wide range of ferrous materials, including steel and iron, makes it a versatile tool for various applications within the metalworking industry. Whether used in fabrication shops, foundries, or heavy machinery manufacturing, the chuck's strong magnetic hold ensures that workpieces remain in place throughout the machining process, reducing the risk of accidents and improving the overall quality of the finished product.

In conclusion, the PMQC Industrial Strong Permanent Magnetic Chuck is a critical component in modern industrial metalworking. Its combination of strong magnetic force, durability, and ease of use makes it an indispensable tool for secure and efficient workpiece holding. Its design and construction reflect a deep understanding of the challenges faced in the industry and provide a solution that enhances both productivity and safety in the workplace.