The Portable Suction Cup Lifter, as detailed on the provided webpage, is a specialized tool designed to facilitate the lifting and handling of various materials in industries such as construction, automotive, glass processing, and more. This tool leverages the power of atmospheric pressure to provide a secure grip on smooth, non-porous surfaces, offering a safe and efficient alternative to traditional lifting methods.

The design of the Portable Suction Cup Lifter is predicated on the principle of vacuum technology. When the air is removed from the suction cup, it creates a partial vacuum that is stronger than the external atmospheric pressure, which in turn holds the suction cup firmly against the surface. The effectiveness of this technology is dependent on several factors, including the quality of the seal, the surface area of the suction cup, and the material being lifted.

The suction cup itself is typically made from high-quality rubber or silicone, materials known for their durability and elasticity. These materials can withstand the compression and expansion that occurs as the vacuum is created and maintained. The cup's shape is also crucial; it must be able to conform to the surface it is applied to, creating a tight seal that prevents air from leaking back into the cup and compromising the vacuum.

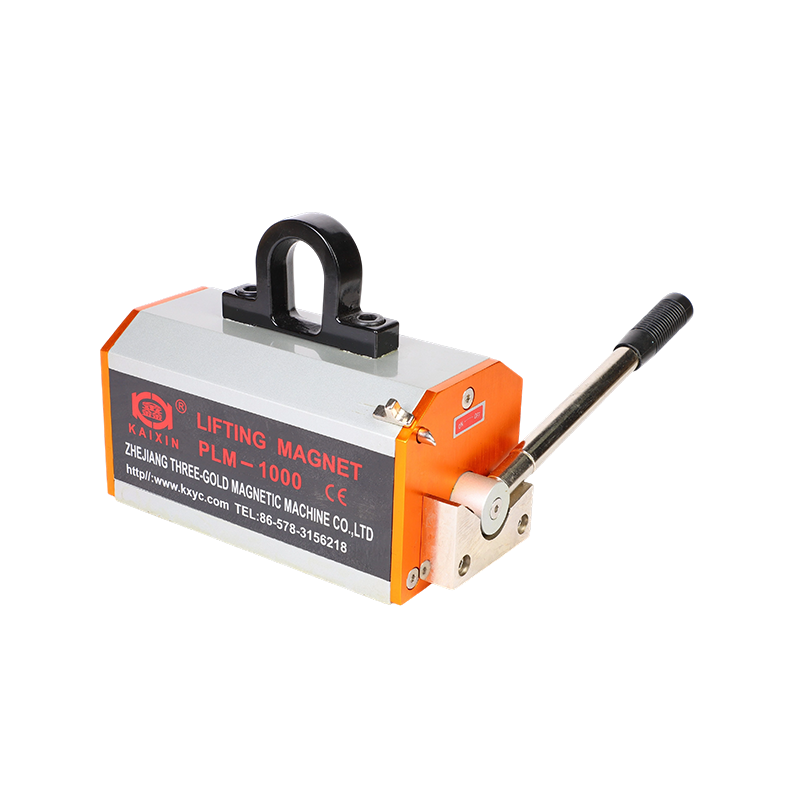

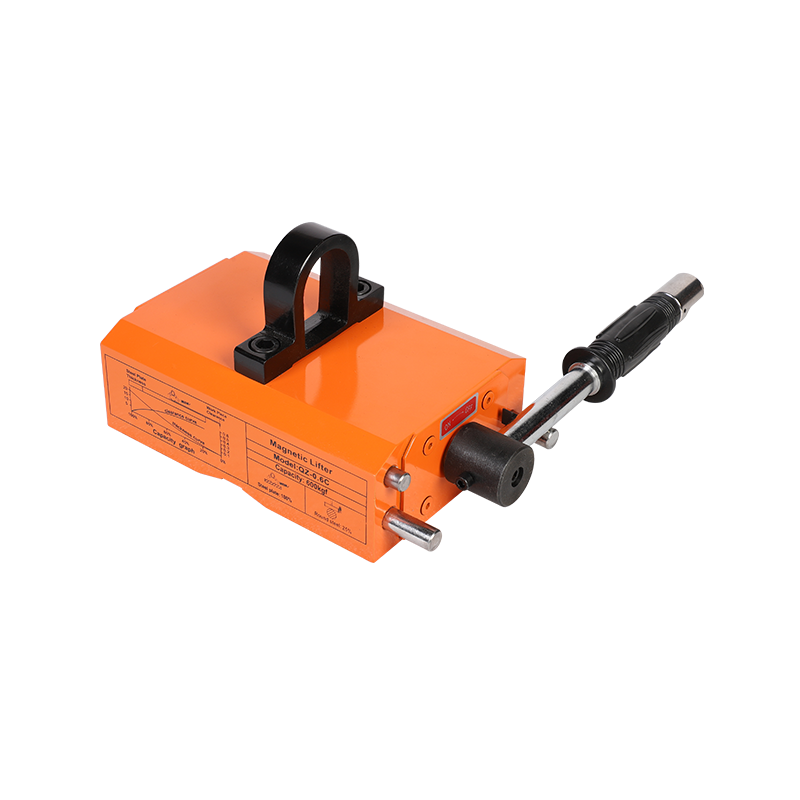

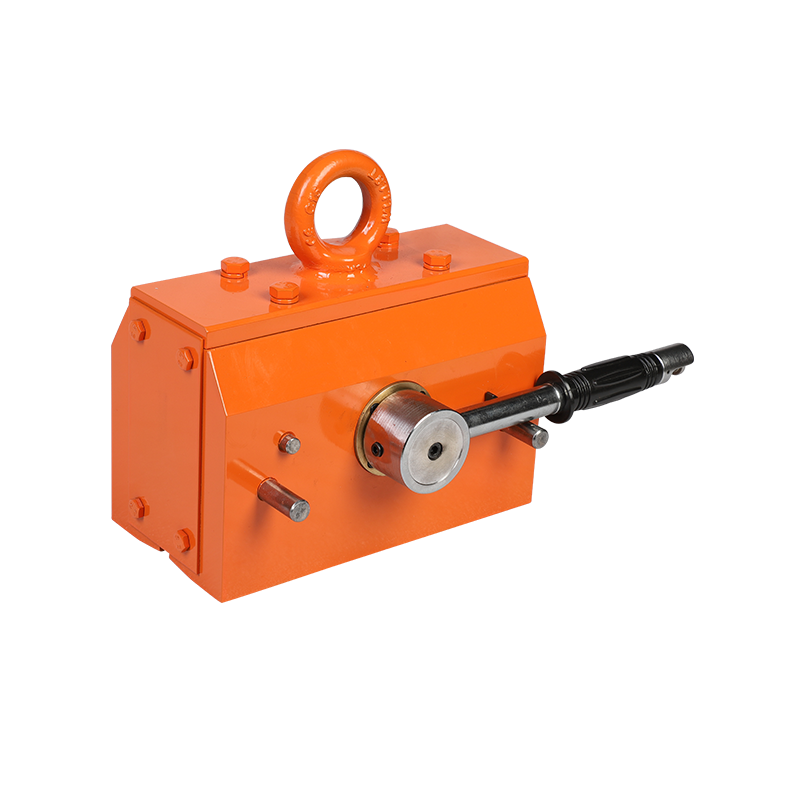

The Portable Suction Cup Lifter often includes additional features to enhance its functionality. For instance, some models come with a manual pump or a valve to control the vacuum level, allowing the user to adjust the suction force to suit the weight and size of the material being lifted. This level of control is vital in ensuring the safety of the operation, as too little suction could result in the material slipping, while too much could damage the surface or the suction cup itself.

The lifter's body is usually made from sturdy materials such as steel or aluminum to ensure it can withstand the forces exerted during lifting. This construction also provides a durable and long-lasting tool that can be used in various environments without fear of damage. Some models may also feature a swivel or rotating mechanism, which allows for greater flexibility in positioning the lifted material, enhancing the tool's versatility.

One of the significant benefits of the Portable Suction Cup Lifter is its portability. The lack of an external power source means that it can be easily transported and used in different locations without the need for electrical hookups or heavy batteries. This makes it a good tool for on-site work or in situations where power is not readily available.

Safety is a paramount concern with any lifting equipment, and the Portable Suction Cup Lifter is no exception. It is designed to have a safety factor that exceeds the load it is rated for, providing a margin of safety to prevent accidents. Additionally, regular inspection and maintenance are crucial to ensure that the suction cups and the lifter itself are in good condition and functioning correctly.

In terms of industry applications, the Portable Suction Cup Lifter is invaluable. In the automotive industry, it can be used to lift and position car windows and windshields with precision. In construction, it can aid in the handling of large glass panels or smooth tiles. In the glass processing industry, it can be used to move large sheets of glass without the risk of damage that comes with other handling methods.

Environmental factors can also impact the performance of the Portable Suction Cup Lifter. High temperatures can cause the rubber or silicone of the suction cup to become less effective, while extreme cold can make the material brittle. Humidity can also affect the ability to create a vacuum, as moisture can interfere with the seal. Therefore, understanding these factors and adjusting the use of the lifter accordingly is essential for suitable performance.

In conclusion, the Portable Suction Cup Lifter is a powerful and versatile tool that offers a safe, efficient, and portable solution for lifting a wide range of materials. Its design, construction, and features make it a valuable asset in various industries, providing a reliable method of material handling that reduces the risk of damage to both the material and the handler. Understanding the principles behind its operation and the factors that can affect its performance is crucial for getting the most out of this indispensable piece of equipment.