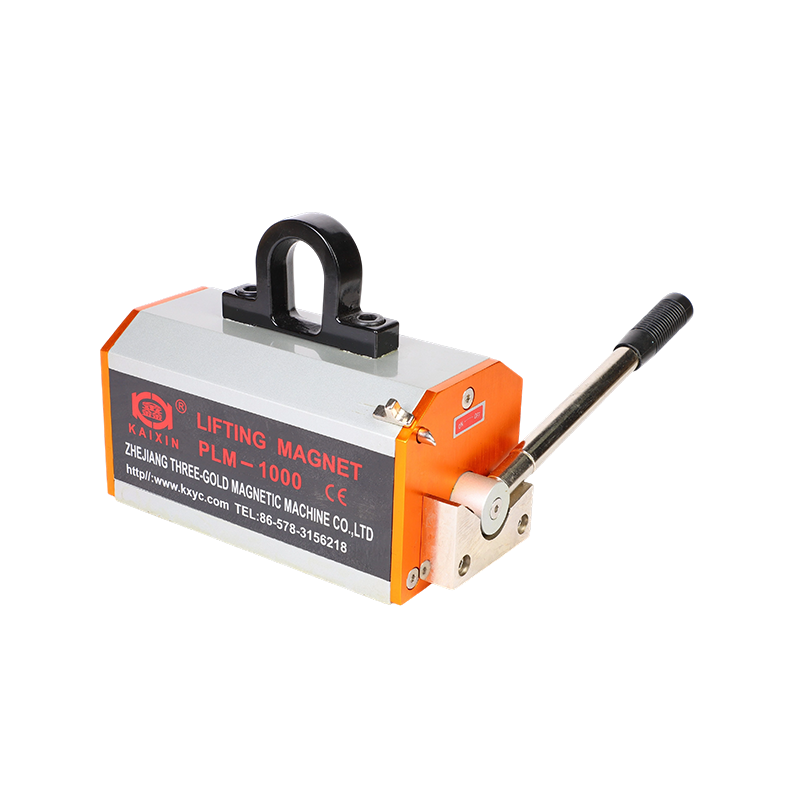

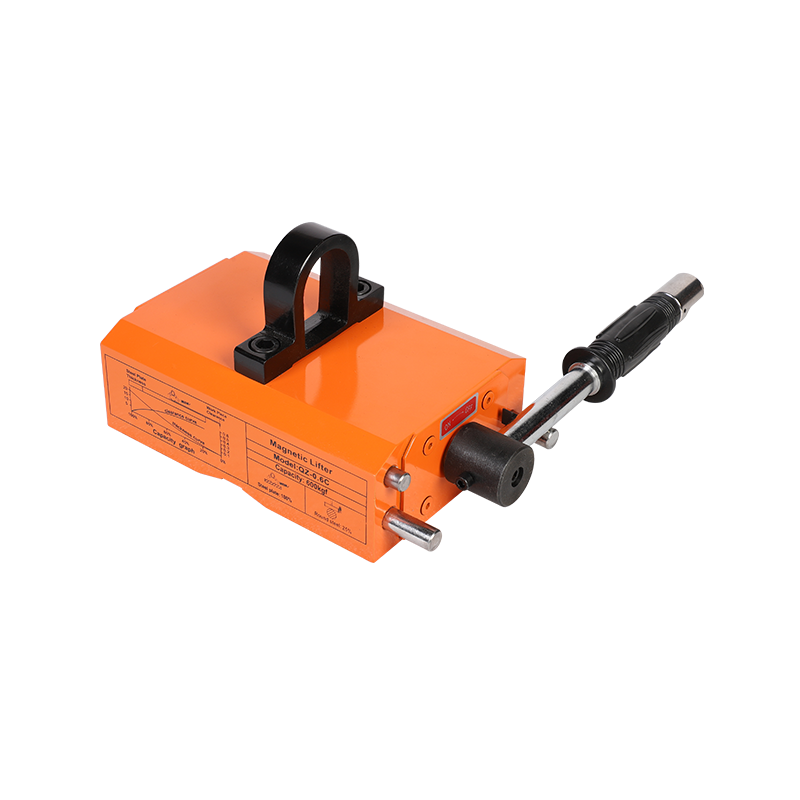

The Permanent Magnetic Chuck Handle is a specialized accessory designed to facilitate the operation of permanent magnetic chucks, which are widely used in machine shops and workshops for holding workpieces securely during processing. This handle is an essential piece of equipment that enhances the usability and safety of magnetic chucks, particularly in applications where precision and control are required.

The handle is engineered to provide a manual means of adjusting the magnetic force exerted by the chuck. It is typically attached to the top of the magnetic chuck and allows the operator to toggle the magnetic field on and off, as well as to adjust the intensity of the magnetic field to suit the specific requirements of the task at hand. This manual control is crucial for applications where the workpiece needs to be released without power tools or additional equipment, such as in the case of small workshops or during maintenance operations.

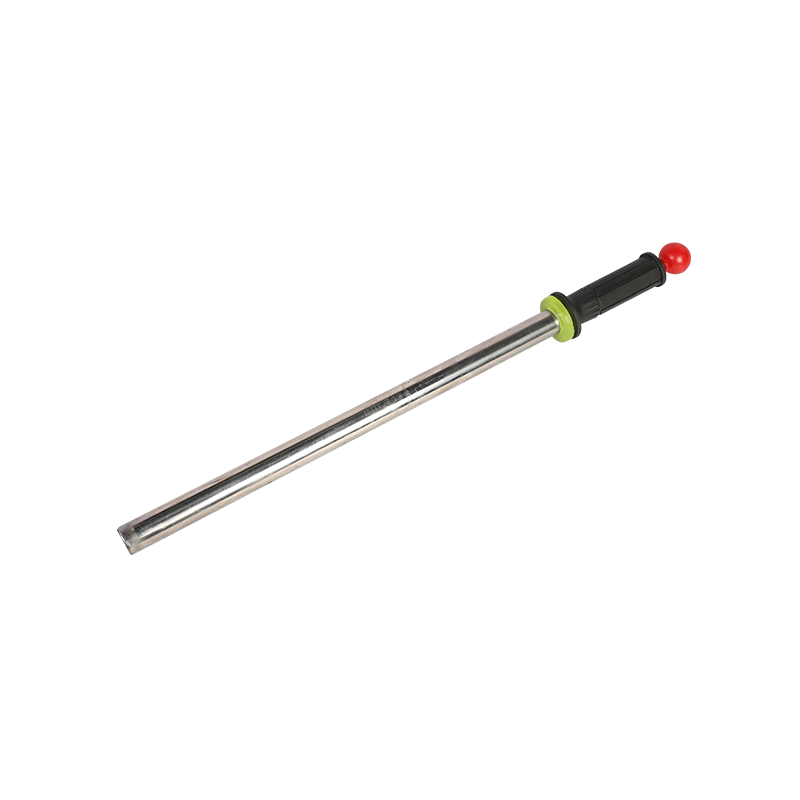

The construction of the Permanent Magnetic Chuck Handle is robust, often made from high-quality materials like steel or aluminum to ensure durability and resistance to wear and tear. The handle is designed to withstand the rigors of industrial use, including exposure to metal filings, coolants, and other workshop fluids. Its ergonomic design ensures a comfortable grip for the operator, reducing fatigue during extended use.

One of the primary benefits of using a Permanent Magnetic Chuck Handle is the ability to quickly and easily change workpieces without the need for additional clamping or unclamping mechanisms. This can significantly reduce setup times and increase productivity in environments where multiple workpieces need to be machined in quick succession.

The handle also plays a critical role in safety by allowing the operator to maintain a safe distance from the magnetic chuck while it is in use. This is particularly important in situations where the magnetic field could potentially attract stray metal objects, posing a risk to personnel or equipment.

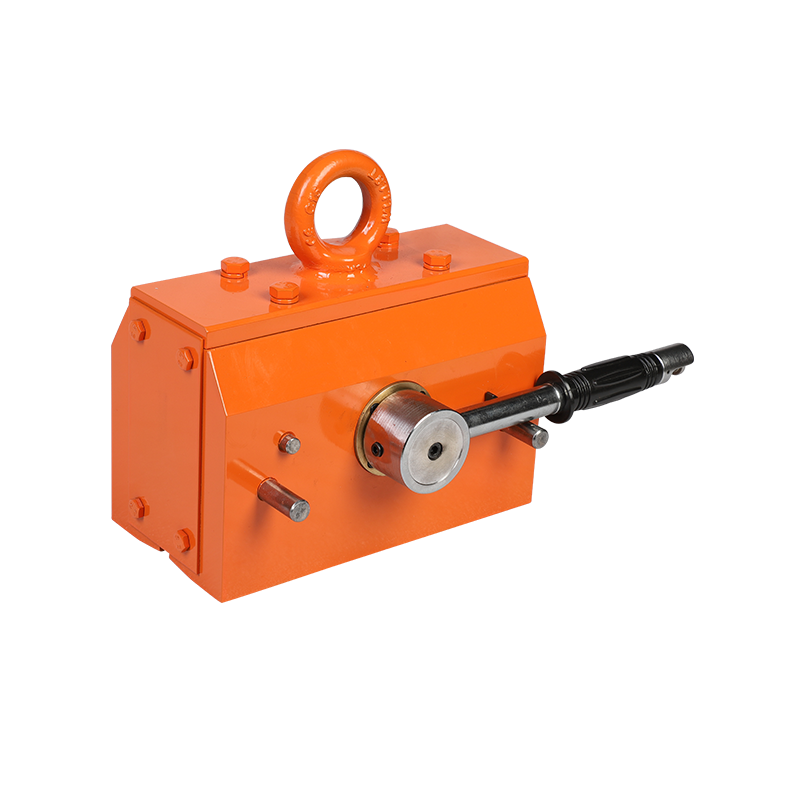

In terms of operation, the Permanent Magnetic Chuck Handle works in conjunction with the magnetic circuit of the chuck. When the handle is turned, it either completes or interrupts the magnetic circuit, thereby activating or deactivating the magnetic field. The handle is typically spring-loaded to ensure that the magnetic field is only active when the handle is deliberately turned on, providing a fail-safe mechanism to prevent accidental activation.

The versatility of the Permanent Magnetic Chuck Handle is evident in its compatibility with a wide range of magnetic chucks, including those with different sizes and magnetic capacities. This compatibility allows workshops to standardize on a single type of handle, simplifying inventory management and reducing costs.

Maintenance of the Permanent Magnetic Chuck Handle is straightforward, with most models requiring only periodic cleaning to remove metal debris and lubrication of moving parts to ensure smooth operation. Some handles also feature replaceable tips or wear plates, which can be swapped out when they become worn, extending the life of the handle and reducing downtime.

The Permanent Magnetic Chuck Handle is a critical accessory that enhances the functionality, safety, and efficiency of permanent magnetic chucks in industrial settings. Its manual control, robust construction, and compatibility with various chucks make it an indispensable tool for any workshop that relies on magnetic chucks for holding workpieces during machining operations. By understanding the importance of this accessory and its role in the overall operation of magnetic chucks, industry professionals can ensure that their workshops are equipped to handle a variety of tasks with precision and safety.