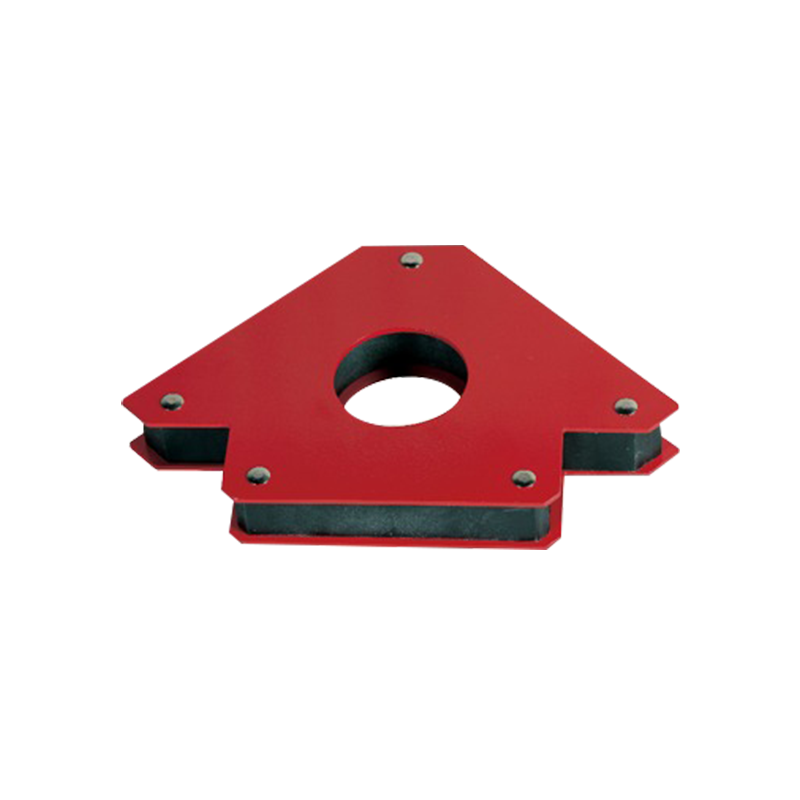

These magnets are essential in ensuring precision and safety during welding operations, particularly in environments where workpieces need to be held in place without the need for additional clamping systems.

The welding magnets offered are designed with a strong magnetic force that can withstand high temperatures and resist demagnetization, which is crucial during the welding process, where heat can reach extreme levels. The magnets are typically made from high-grade materials such as neodymium or ferrite, which are known for their good magnetic properties.

One of the key benefits of using welding magnets is their ability to hold metal pieces firmly in place without causing any damage to the surface. This is particularly important in precision welding, where the integrity of the workpiece must be maintained. The non-marring feature of these magnets ensures that there are no marks or scratches left on the metal, preserving the quality of the finished product.

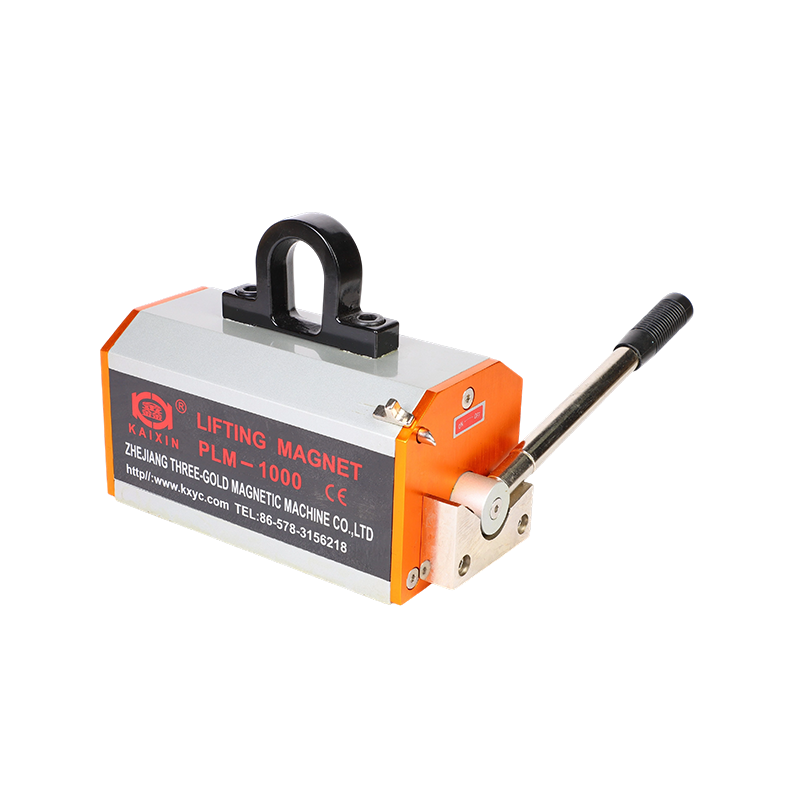

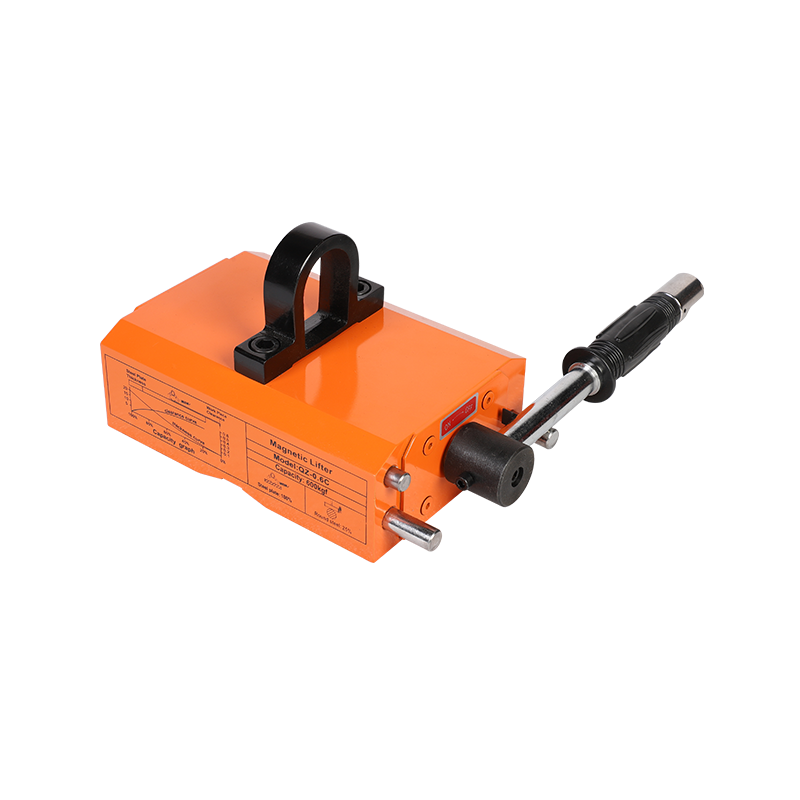

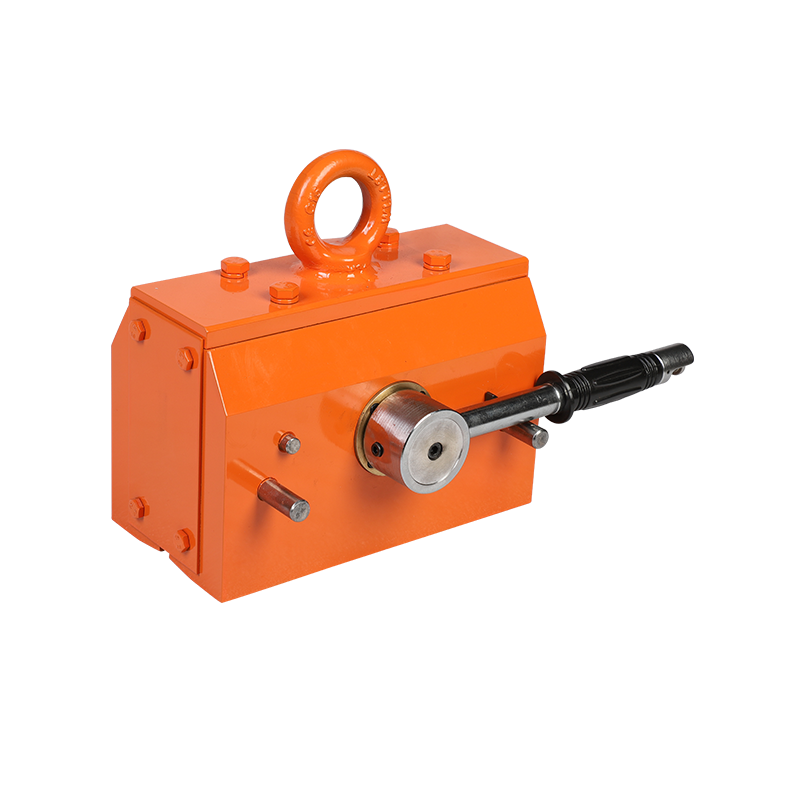

The magnets are often equipped with a quick-release mechanism that allows for easy detachment of the workpiece once the welding is complete. This feature is not only convenient but also efficient, as it saves time and effort compared to traditional clamping methods. The quick-release function is often activated by a simple lever or handle, which can be operated with a gloved hand, ensuring safety and ease of use in a workshop environment.

Welding magnets come in various sizes and shapes to accommodate different types of workpieces and welding projects. Some are designed to hold small, intricate parts, while others are built to handle large, heavy structures. The shape of the magnet can also be tailored to fit specific welding applications, such as flat surfaces, curved surfaces, or even irregularly shaped workpieces.

In addition to their use in welding, these magnets can be employed in other metalworking processes where secure holding is required. For instance, they can be used in metal fabrication, metal cutting, and even in assembly work where parts need to be held in place for alignment or fitting.

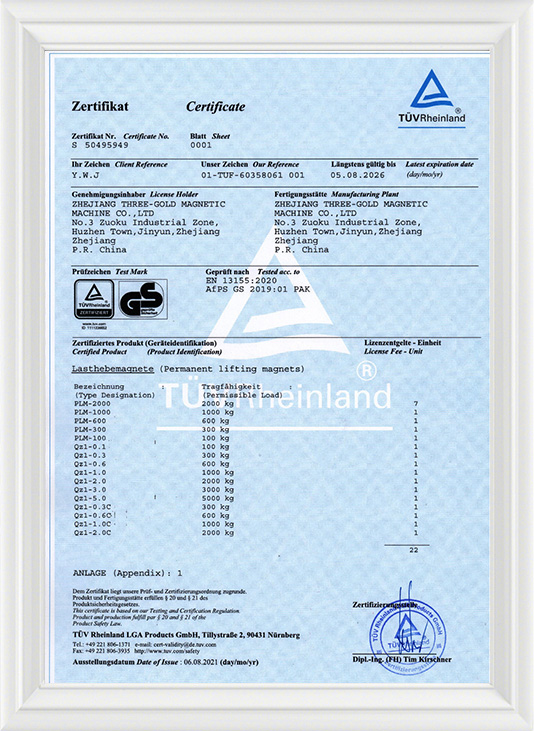

The strength of welding magnets is often indicated in terms of their pull force, which is the amount of weight they can hold. This force is crucial in determining the suitability of a magnet for a particular job. A magnet with a higher pull force is more suitable for heavy-duty applications, while a lower force magnet may be adequate for lighter workpieces.

The durability of welding magnets is another important consideration. In a harsh industrial environment, magnets must be able to withstand not only high temperatures but also physical wear and tear. High-quality welding magnets are designed with robust construction to ensure longevity and consistent performance over time.

Safety is a paramount concern when using welding magnets. It is essential to ensure that the magnets are used within their specified temperature and weight limits to prevent accidents. Additionally, proper handling and storage of these magnets are crucial to avoid any potential hazards, such as the accidental attraction of metal objects that could cause injury.

Welding magnets are indispensable tools in the welding and metalworking industries. They provide a secure, non-damaging, and efficient method of holding workpieces during the welding process. With their adjustable strength, quick-release mechanisms, and robust construction, these magnets enhance productivity and safety in the workshop. Understanding the properties and capabilities of welding magnets is essential for professionals in the field to make the most of these tools and ensure the high standards of workmanship.