The Suspended Permanent Magnetic Separator is a crucial piece of equipment in industries where the separation of ferrous materials from non-ferrous ones is essential.

The separator operates on the principle of permanent magnetism, utilizing powerful rare-earth magnets or ceramic magnets to create a magnetic field that attracts and holds ferrous materials. The strength and configuration of the magnetic field are designed to capture even the small pieces of metal, preventing them from contaminating the processed material or damaging downstream equipment.

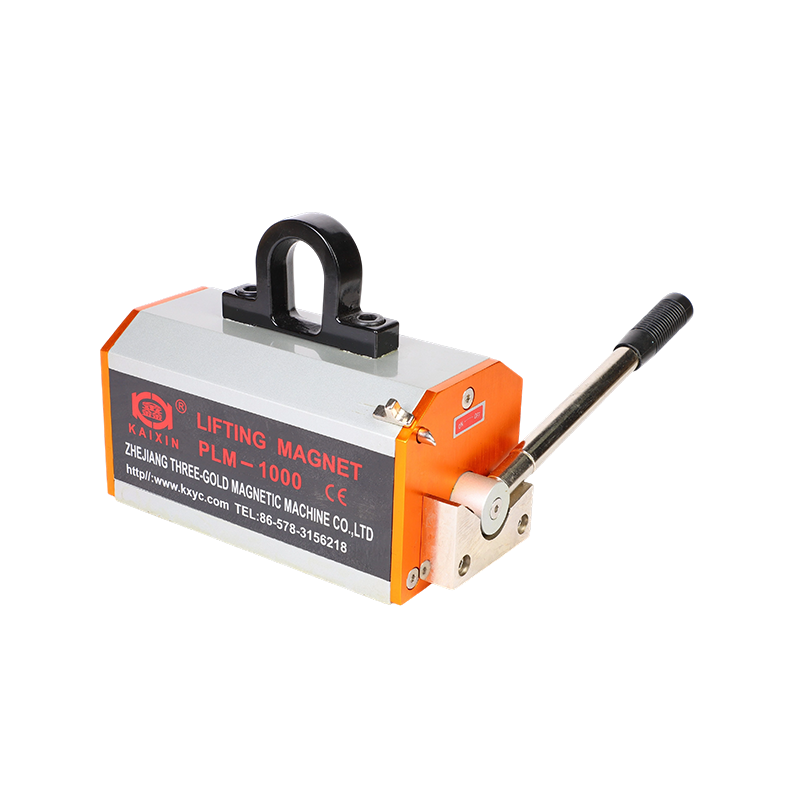

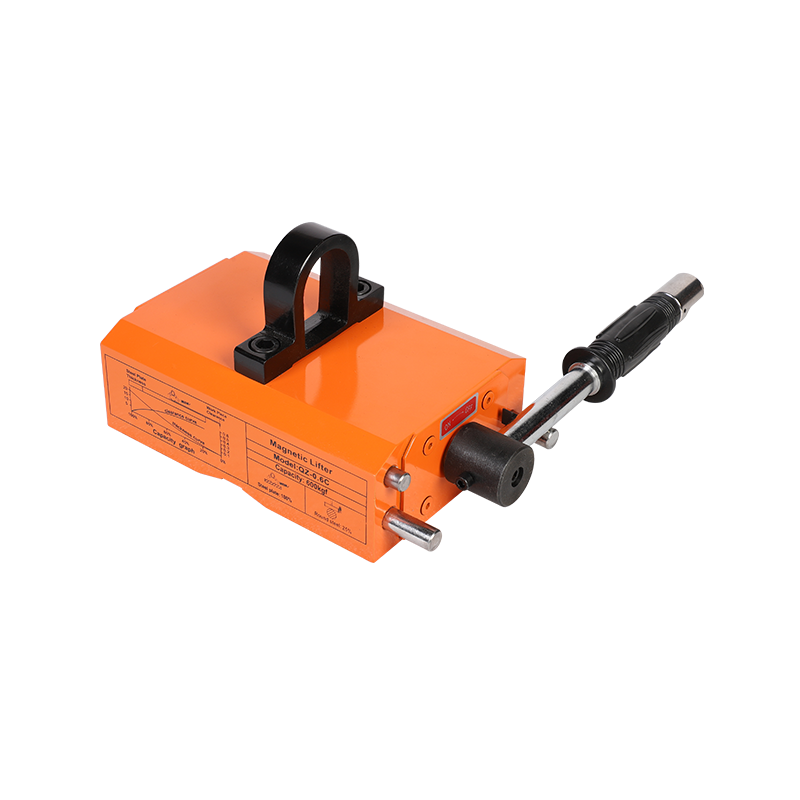

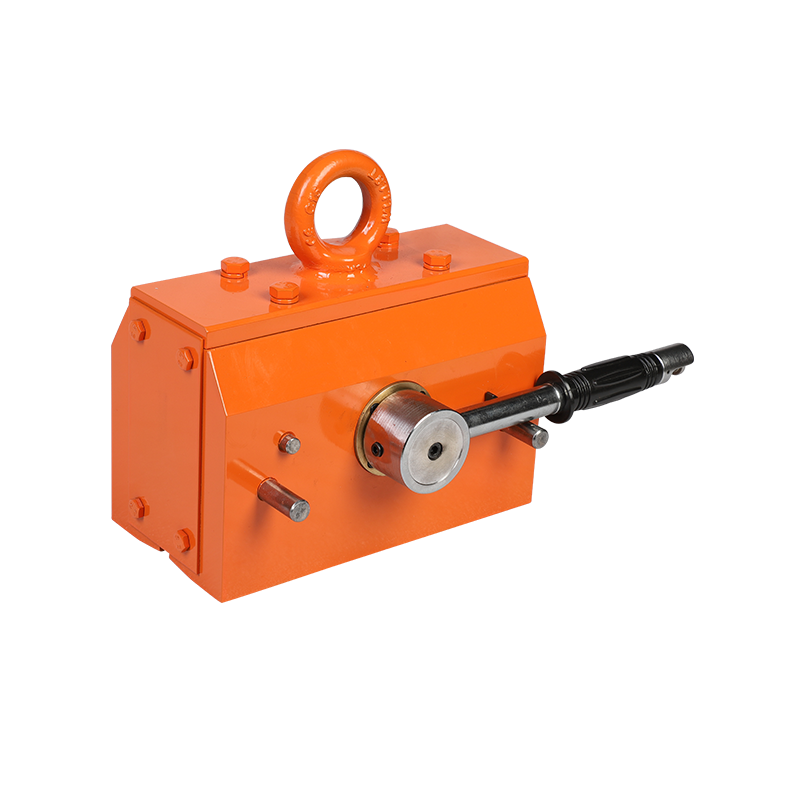

The construction of the Suspended Permanent Magnetic Separator is robust, featuring a durable frame that can withstand the rigors of industrial use. The magnets are housed within a protective casing, which not only shields the magnets from physical damage but also from the elements, ensuring their longevity and consistent performance. The casing is typically made from materials that are resistant to corrosion, such as stainless steel, which is particularly important in environments where the separator is exposed to moisture or chemicals.

One of the key features of this magnetic separator is its ability to be suspended, which allows for the magnetic field to be positioned directly in the path of the material flow. This design enables the separator to intercept and remove ferrous particles before they can cause issues further down the line. The suspension system is engineered to support the weight of the separator and the caught metals, ensuring stability and safety during operation.

The separator is also designed to be easily cleaned and maintained. The captured ferrous materials can be easily released from the magnetic field, allowing for their disposal or recycling. This feature is crucial for maintaining the efficiency of the separator, as a buildup of ferrous materials can reduce the effectiveness of the magnetic field.

In the context of recycling, the Suspended Permanent Magnetic Separator is indispensable for the sorting of metal scraps. It helps in the separation of ferrous metals such as iron and steel from non-ferrous metals and other materials, facilitating the process of recycling and reducing waste. The separator's ability to handle large volumes of material makes it an efficient solution for high-throughput recycling operations.

In food processing, the separator is a critical component in ensuring food safety. It prevents foreign metal objects from contaminating food products, which could cause product recalls, legal issues, and health risks for consumers. The separator's magnetic field is strong enough to catch even small metal fragments that could otherwise go undetected.

In mining operations, the Suspended Permanent Magnetic Separator is used to remove metallic contaminants from ore before it is processed. This helps to improve the efficiency of the processing equipment and the quality of the final product. The separator can also be used to recover valuable metals that may be present in the ore, adding to the profitability of the mining operation.

The separator's performance can be tailored to suit specific applications through the adjustment of the magnetic field strength and the size of the magnetic plates. This flexibility allows the separator to be used in a wide range of industries and applications, from small-scale food processing plants to large-scale mining operations.

The Suspended Permanent Magnetic Separator is a versatile and essential tool in many industries. Its ability to reliably separate ferrous materials from non-ferrous ones contributes to the efficiency, safety, and quality of various processes. As industries continue to evolve and the demand for clean, uncontaminated materials increases, the role of the Suspended Permanent Magnetic Separator will remain crucial in maintaining standards and protecting against potential hazards.