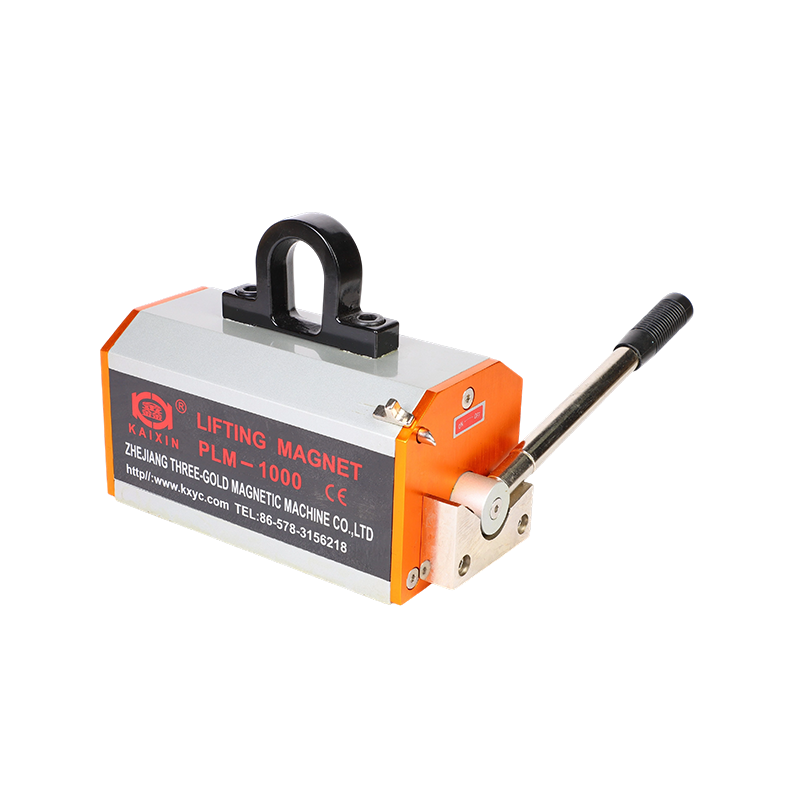

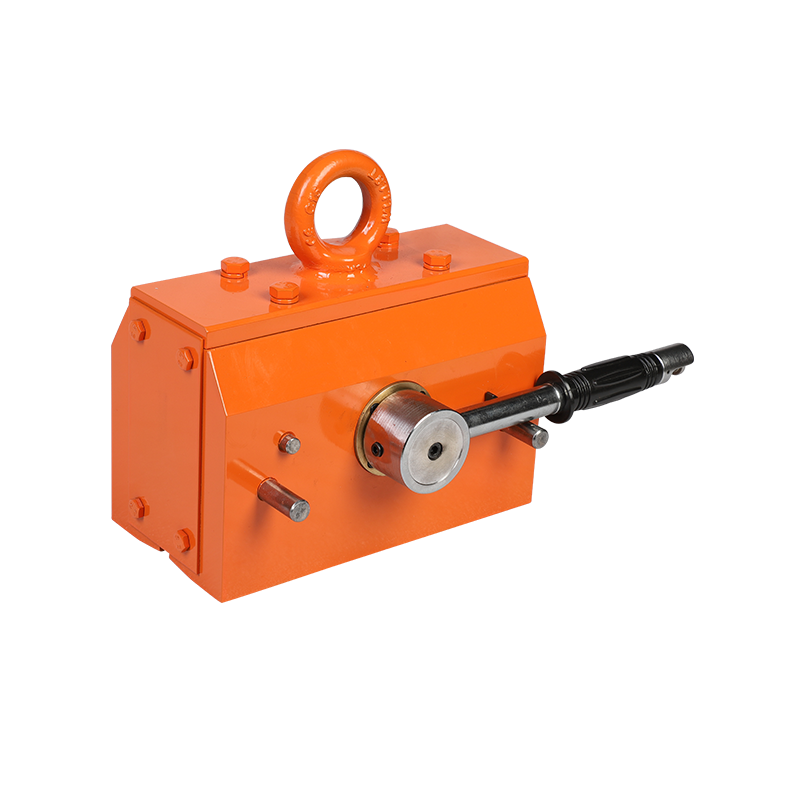

The QZ3 is designed to handle heavy ferrous materials with ease and precision. Its automatic operation decreases the risk of accidents and reduces the physical strain on workers, which is particularly important in environments where heavy lifting is a common task. The device's magnetic force is generated by rare-earth neodymium magnets, known for their high magnetic strength and reliability. These magnets are embedded within the device in a way that ensures a uniform and powerful grip on the material being lifted.

One of the key advantages of the QZ3 is its automatic locking mechanism. Once the magnetic force is engaged, the device automatically locks, ensuring that the load remains secure even if the lifting handle is released. This feature is crucial for safety, as it prevents accidental drops and potential damage to both the load and the surrounding equipment or personnel.

The QZ3 is also designed with a fail-safe mechanism that guarantees the magnetic force will not decrease during the lifting process. This is achieved through the use of a redundant magnetic circuit, which ensures that even if one part of the circuit fails, the magnetic force remains intact. This redundancy is a critical safety feature that sets our product apart from others in the market.

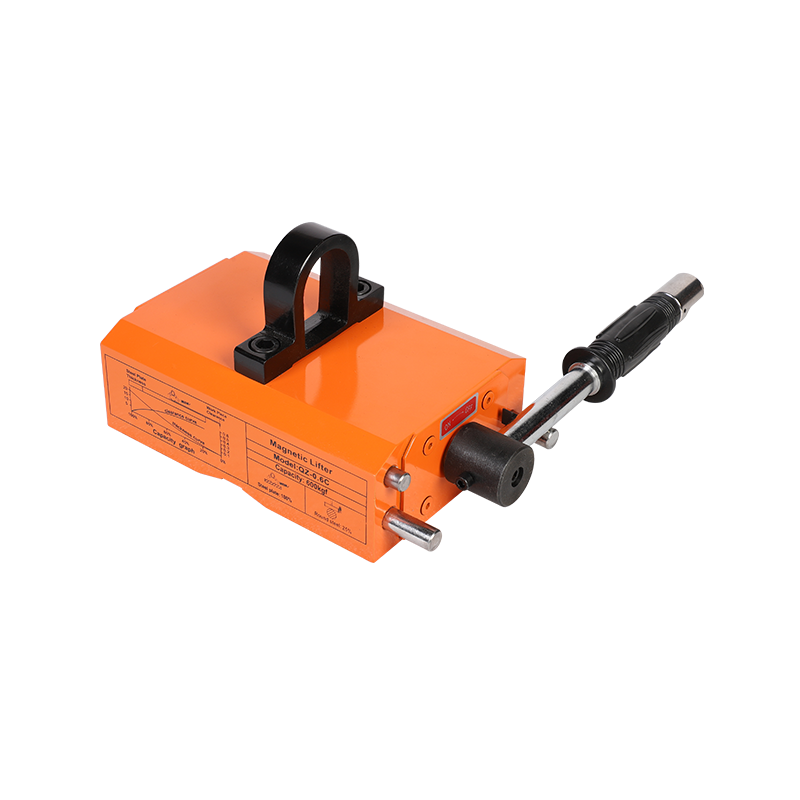

In terms of versatility, the QZ3 is compatible with a wide range of ferrous materials, making it a valuable asset in various industries such as steel manufacturing, construction, automotive, and shipbuilding. Its portability and ease of use make it an ideal choice for both indoor and outdoor applications, where lifting and moving heavy materials is a common requirement.

The device is also low maintenance, thanks to its lack of moving parts that could wear out or require regular servicing. This not only reduces operational costs but also ensures that the QZ3 remains a reliable tool for the long term. The absence of electrical components also means that there is no risk of electrical hazards, making it a safe option for use in wet environments.

The QZ3's ergonomic design is another aspect that sets it apart. The lifting handle is positioned to provide leverage, making it easier for operators to lift and maneuver heavy loads. This design consideration not only improves efficiency but also helps to prevent strain and injury to the operator.

In the context of environmental considerations, the QZ3 contributes to a greener industrial process by reducing the need for energy-intensive lifting equipment. Its magnetic operation means that there is no need for electricity, which can cause significant energy savings and a reduced carbon footprint.

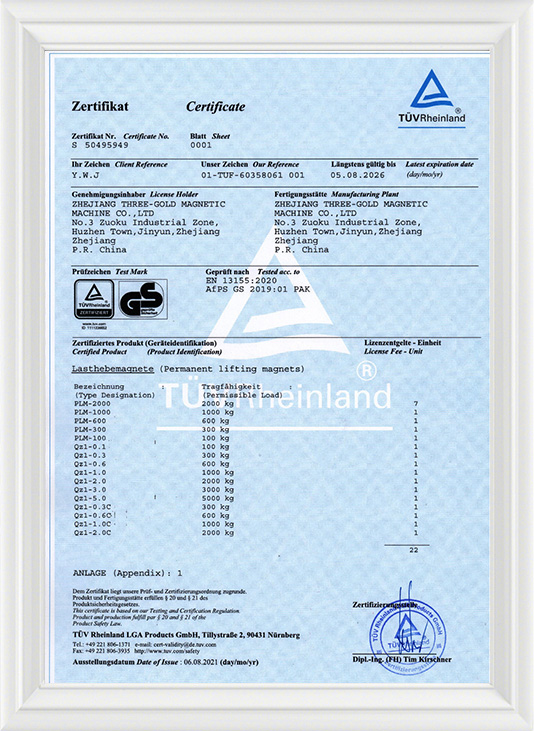

Lastly, as a manufacturer, we understand the importance of regulatory compliance and safety standards. The QZ3 is designed and tested to meet these standards, ensuring that it can be used with confidence in a wide range of applications. We also offer comprehensive training and support to our customers, ensuring that they can use the QZ3 safely and effectively.

The QZ3 Model Automatic Permanent Magnet Lifting Device is a testament to our dedication to engineering well and customer satisfaction. It represents a significant advancement in the field of magnetic lifting, offering a solution that is safe, efficient, versatile, and environmentally friendly. As a manufacturer, we are proud to offer such a product and look forward to seeing how it contributes to the success of our customers' operations.