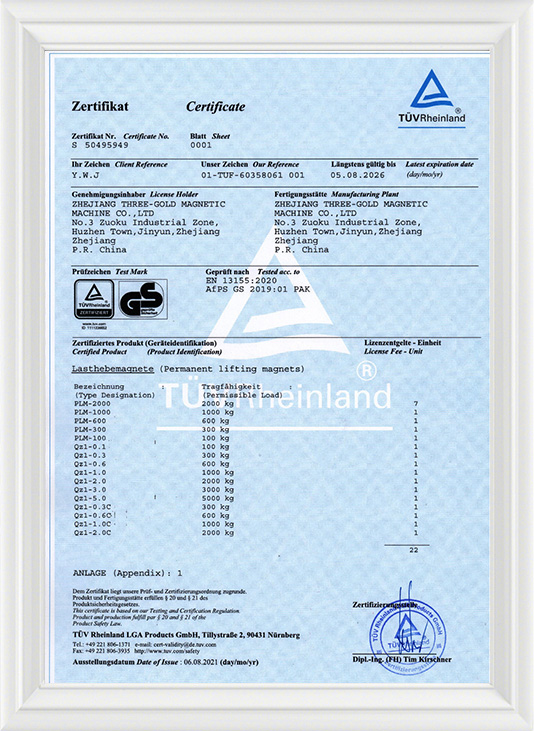

The PML Industrial Durable Permanent Magnetic Lifter, as showcased on the provided webpage, is a specialized piece of equipment designed for the safe and efficient handling of ferrous materials in industrial settings. This product is a prime example of how modern engineering and material science come together to create tools that can change the way industries operate. Here, we delve into the professional industry knowledge surrounding this product, highlighting its features, benefits, and applications.

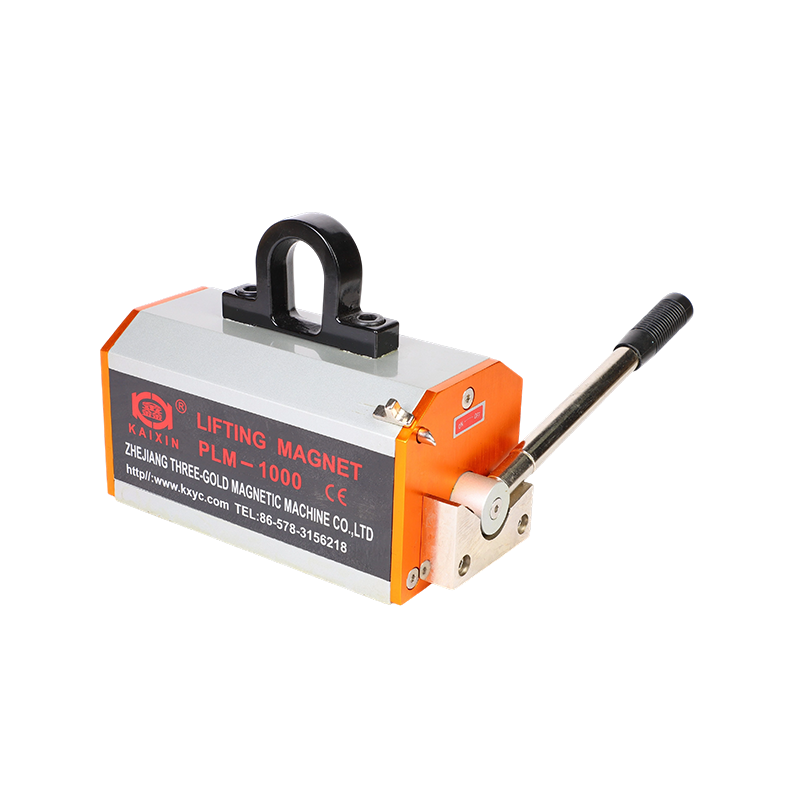

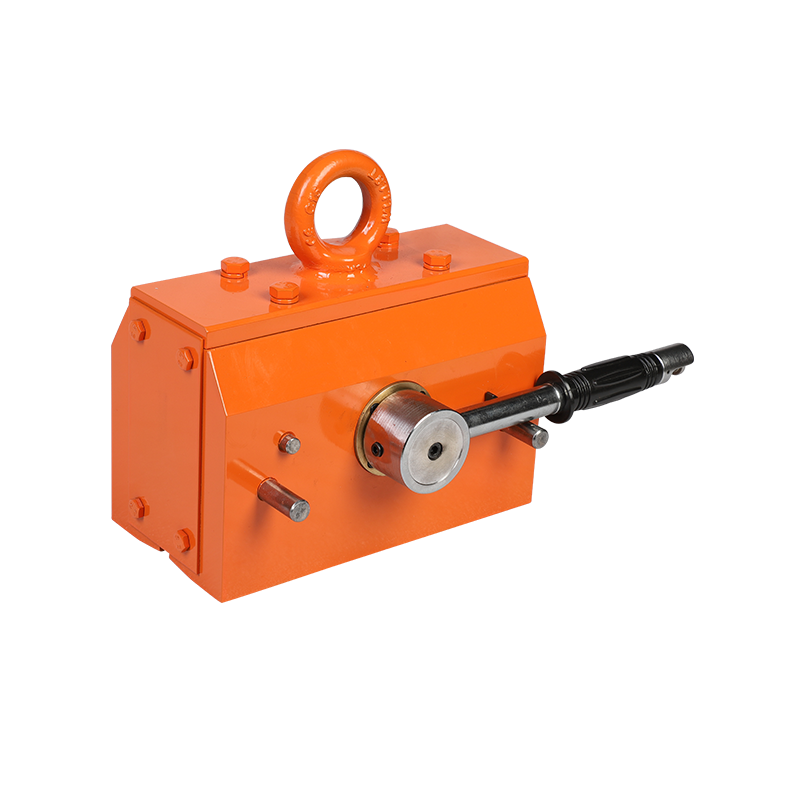

Designed with robust construction in mind, the PML Industrial Durable Permanent Magnetic Lifter is crafted to withstand the harsh conditions of industrial environments. It utilizes powerful rare-earth magnets, which are renowned for their high magnetic strength and resistance to demagnetization. These magnets are enclosed within a protective casing, ensuring that they remain effective even in the presence of dirt, dust, and other contaminants commonly found in workshops and factories.

One of the key features of this permanent magnetic lifter is its ability to provide a secure grip on ferrous materials without the need for electricity. This makes it an ideal choice for environments where power outages or electrical hazards are a concern. The absence of electrical components also reduces the risk of electrical sparks, which is particularly important in industries where flammable materials are handled.

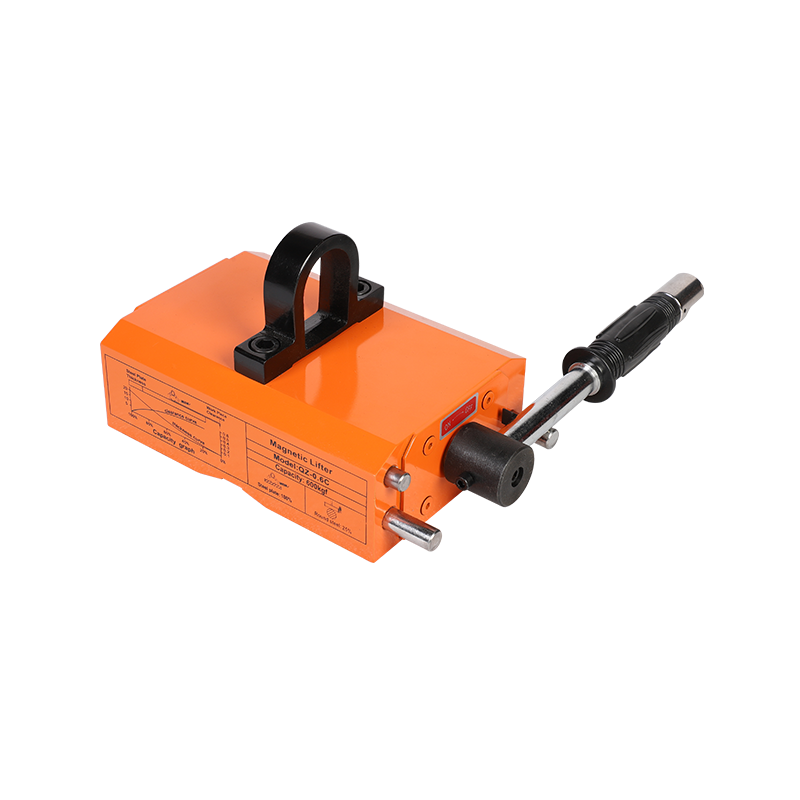

The PML Industrial Durable Permanent Magnetic Lifter is designed with a manual release mechanism, allowing operators to quickly and safely release the load when needed. This feature is crucial for preventing accidents and ensuring the safety of workers. The lifter's manual operation also means that it can be used in areas where access to power is limited or non-existent, making it a versatile tool for various applications.

In terms of safety, the PML Industrial Durable Permanent Magnetic Lifter is equipped with a safety factor that exceeds industry standards. This means that the lifter is capable of holding a load well beyond its rated capacity, providing a margin of safety that is essential in heavy-duty lifting operations. The lifter also features visual and tactile indicators that alert the operator when the device is approaching its capacity, further enhancing safety during use.

The lifter is engineered to handle a wide range of ferrous materials, including steel plates, bars, and blocks. Its versatility makes it an invaluable tool in industries where such materials are commonly used. The PML Industrial Durable Permanent Magnetic Lifter can be used in applications such as lifting steel beams for construction, loading and unloading steel coils in shipping yards, or moving heavy machinery components in manufacturing plants.

Maintenance of the PML Industrial Durable Permanent Magnetic Lifter is minimal due to its solid-state design. There are no moving parts that can wear out or require lubrication, which means that downtime for maintenance is significantly reduced. This not only saves on maintenance costs but also increases the overall productivity of the operation.

The lifter's compact design makes it easy to maneuver in tight spaces, and its lightweight ensures that it can be easily transported from one worksite to another. This portability is a significant advantage in industries that require frequent relocation of lifting equipment.

The PML Industrial Durable Permanent Magnetic Lifter is a product that embodies the advancements in material handling technology. It is a reliable, safe, and efficient solution for industries that require the handling of ferrous materials. Its design, incorporating powerful rare earth magnets, a manual release mechanism, and a high safety factor, makes it a preferred choice for heavy-duty lifting tasks. By understanding the intricacies of this product, industry professionals can appreciate the benefits it brings to their operations, enhancing safety, efficiency, and productivity.