One of the primary benefits of magnetic tools is their ability to handle heavy loads with precision and reliability. The strength of the magnetic field generated by these tools is a critical aspect, often measured in Gauss or Tesla. The higher the Gauss rating, the stronger the magnetic attraction, allowing the tool to lift heavier loads. The magnetic tools on the webpage are likely to feature high Gauss ratings, ensuring they can handle the rigors of industrial use.

The materials used in the construction of these tools are another important consideration. High-quality materials like neodymium magnets are often employed for their good magnetic properties. Neodymium magnets are known for their high magnetic strength and resistance to demagnetization, making them ideal for heavy-duty applications. The tool's body may be made from durable materials such as high-strength steel or aluminum, which provide structural integrity without adding excessive weight.

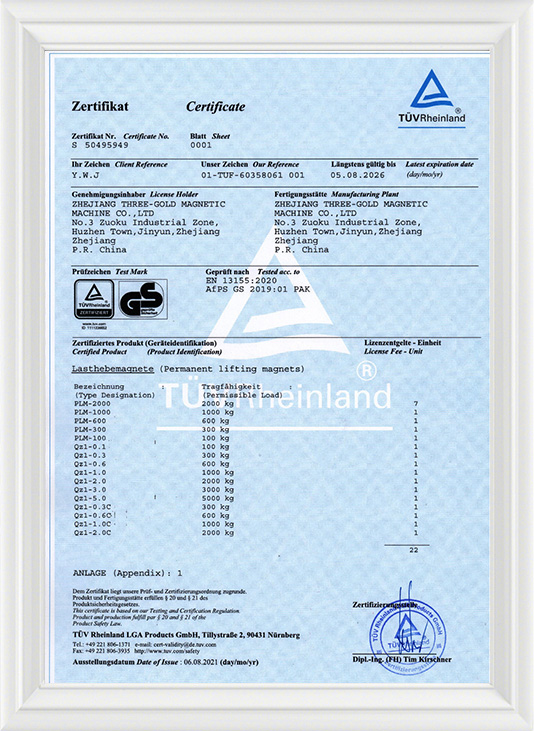

Safety is paramount in any industrial setting, and the magnetic tools on the webpage are likely designed with safety features to prevent accidents. These may include a safety latch or release mechanism that ensures the tool does not accidentally release its load. Additionally, some tools may have a built-in overload protection system that prevents damage to the tool and potential injury to workers if the magnetic tool is subjected to a load beyond its capacity.

The ergonomic design of the magnetic tools is another crucial factor. Tools that are easy to handle and operate can reduce operator fatigue and improve productivity. Features such as comfortable grip handles, easy-to-reach control buttons, and a balanced weight distribution contribute to user comfort and efficiency. The tools may also be designed to be ambidextrous, accommodating both right-handed and left-handed users.

Portability is another feature that enhances the utility of magnetic tools. Lightweight models can be easily carried from one work site to another, while still providing the necessary strength to handle heavy materials. This is particularly important in construction and similar industries where tools may need to be moved frequently.

Magnetic tools also offer environmental benefits, as they reduce the need for manual lifting and the associated risk of back injuries. By using magnetic force to lift and move materials, these tools can help to create a safer working environment and reduce the incidence of work-related injuries.

In terms of maintenance, magnetic tools should be kept clean and free from debris to ensure suitable performance. Regular inspection of the magnetic surface for chips or damage can also prolong the life of the tool. It's important to follow the manufacturer's guidelines for use and care to ensure the tool operates at good efficiency.

The versatility of magnetic tools is another aspect that sets them apart. They can be used in a variety of applications, from lifting steel beams in construction to sorting metals in recycling facilities. This adaptability makes them an invaluable asset in a range of industries.

In conclusion, the magnetic tools featured on the webpage are engineered to provide a combination of strength, safety, and convenience. They are designed to meet the demands of heavy-duty industrial applications while prioritizing user safety and ease of use. As the technology continues to advance, these tools are likely to become even more sophisticated, offering greater capabilities and performance.