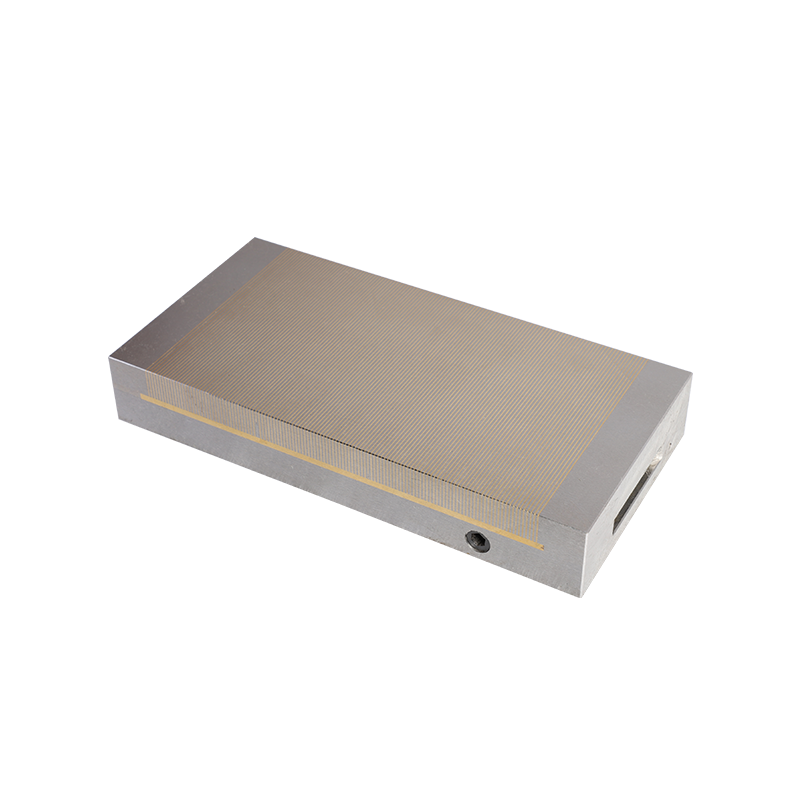

Permanent Magnetic Chucks are widely used in machining and metalworking for securely holding ferromagnetic workpieces during grinding, milling, or drilling operations. Their ability to generate a strong magnetic field allows for stable clamping without the need for mechanical clamps or external power. While these devices provide convenience and efficiency, their performance can be affected by the dimensions and thickness of the workpiece. Understanding how these factors influence stability is essential for safe and precise machining operations.

Influence of Workpiece Thickness on Magnetic Holding Force

The thickness of a workpiece directly impacts the holding capacity of a Permanent Magnetic Chuck. Thicker workpieces provide more material for the magnetic field to engage, resulting in stronger adhesion and improved stability. Conversely, thinner plates may not offer sufficient mass to fully interact with the magnetic field, leading to a reduced clamping force. Operators must consider the minimum thickness requirements specified by manufacturers to ensure that the workpiece is securely held throughout the machining process.

Effects of Workpiece Size and Surface Area

The surface area of the workpiece in contact with the magnetic chuck also plays a critical role in maintaining stability. Larger workpieces allow for more magnetic flux distribution, increasing overall holding force and minimizing the risk of movement during cutting or grinding. In contrast, smaller workpieces may have limited contact, which can result in uneven force distribution and potential shifting. Proper positioning and alignment are necessary to maximize contact between the chuck and the workpiece to achieve optimal stability.

Material Properties and Their Interaction with Thickness

The composition of the workpiece material interacts with thickness and size to affect magnetic holding performance. High-permeability metals such as mild steel respond well to the magnetic field, even at reduced thicknesses, while alloys with lower magnetic permeability may require thicker sections to achieve the same level of stability. Understanding the material’s magnetic characteristics alongside geometric considerations ensures that the chuck can hold the workpiece securely without compromising safety or precision.

Practical Implications in Machining Operations

Variations in thickness and size directly influence machining outcomes. Insufficient holding force due to thin or small workpieces can lead to vibrations, shifting, or inaccurate cuts, negatively impacting surface finish and dimensional precision. On the other hand, overly thick or large pieces may require additional handling precautions to prevent tipping or unbalanced loads. Awareness of these factors helps machinists plan operations effectively, ensuring both safety and high-quality results.

Practices for Enhancing Stability

To optimize the stability of a Permanent Magnetic Chuck, operators should ensure maximum contact area, properly align workpieces, and verify material compatibility. Using auxiliary supports or shims for thin workpieces can increase contact and enhance magnetic holding force. Routine inspection and cleaning of the chuck surface prevent debris from reducing magnetic engagement, further ensuring reliable performance across varying workpiece sizes and thicknesses.

Material and Geometric Considerations for Reliable Use

Permanent Magnetic Chucks provide a versatile and efficient solution for holding ferromagnetic workpieces, but stability is highly dependent on the thickness, size, and material properties of the workpiece. Thicker and larger pieces generally offer stronger adhesion, while thin or small components require careful attention to ensure safety and machining precision. By considering geometric and material factors and following best practices, operators can maximize the effectiveness of magnetic chucks, achieving consistent and secure performance across diverse industrial applications.