Permanent Magnetic Chucks are widely employed in metalworking and machining for securely holding ferromagnetic workpieces during grinding, milling, and other operations. Their ability to generate a strong magnetic field allows for stable clamping without the need for external power sources or mechanical clamps. While these devices are reliable and convenient, ensuring safety during operation is critical. Understanding the safety factors and overload protection mechanisms embedded in Permanent Magnetic Chucks is essential for preventing accidents and maintaining operational efficiency.

Understanding Safety Factors in Magnetic Chuck Design

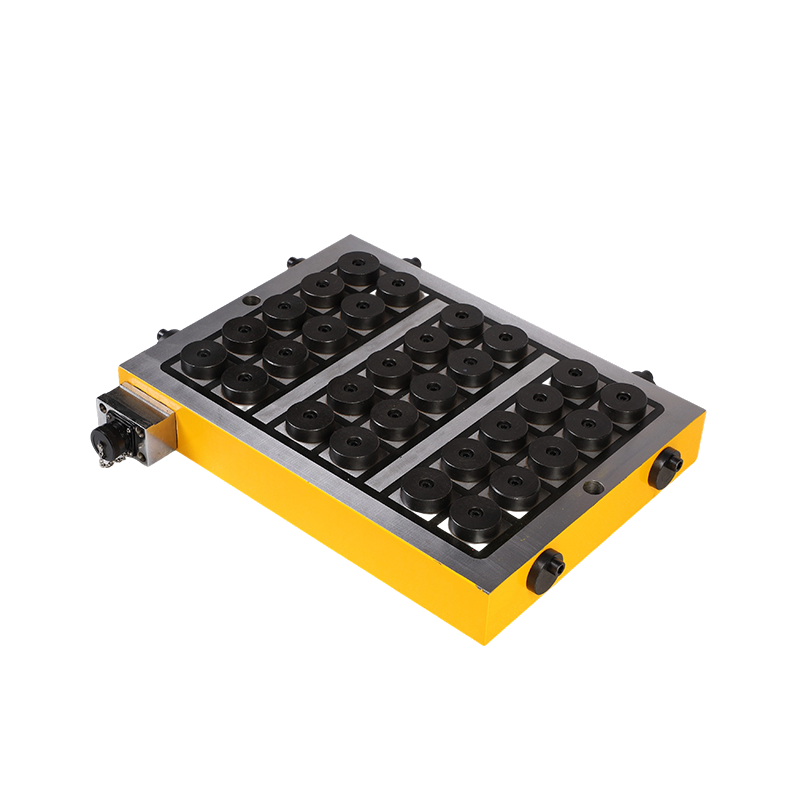

The safety factor of a Permanent Magnetic Chuck refers to the ratio between the maximum holding capacity of the device and the actual working load it is expected to handle. Manufacturers typically design these chucks with a safety factor ranging from 2:1 to 3:1, meaning the chuck can hold two to three times the intended load without risk of failure. This margin accounts for variations in workpiece geometry, material properties, and surface conditions that may affect the actual magnetic force. Adhering to the recommended safety factor ensures that the workpiece remains securely in place even under demanding operational conditions.

Material and Magnetic Considerations Affecting Safety

The material composition of both the chuck and the workpiece plays a crucial role in determining the effective safety factor. Ferromagnetic materials with high permeability allow the magnetic field to fully engage, maximizing holding strength. Conversely, alloys or materials with lower magnetic responsiveness may reduce the effective holding force. Designers account for these variations by specifying reduced load limits or incorporating additional safety margins to prevent unintended slippage. Surface conditions such as rust, paint, or debris can also interfere with magnetic adhesion, emphasizing the importance of clean and properly prepared workpieces.

Overload Protection Mechanisms

Permanent Magnetic Chucks are generally designed to resist accidental overload through mechanical and operational measures. Some models incorporate built-in visual or mechanical indicators to show whether the magnetic field is fully engaged or if the workpiece is improperly seated. In addition, proper operational procedures, such as avoiding sudden impacts or lifting loads beyond rated capacity, act as practical overload protection mechanisms. While these chucks do not feature electronic cutoffs like powered systems, their robust design and inherent magnetic strength provide a reliable buffer against moderate overload conditions.

Operational Safety Practices

To further ensure safety, operators are encouraged to follow strict guidelines when using Permanent Magnetic Chucks. This includes verifying workpiece weight relative to the chuck’s rated capacity, ensuring maximum surface contact, and positioning workpieces to prevent tipping or unbalanced loads. Routine inspection of the chuck’s surface, magnetic elements, and any mechanical indicators helps maintain consistent performance. Additionally, using secondary support mechanisms or clamps for particularly critical or heavy operations adds an extra layer of protection.

Implications for Industrial Applications

In industrial settings, the combination of a conservative safety factor and practical overload protection measures makes Permanent Magnetic Chucks a dependable choice for repetitive and precision machining tasks. By understanding the limitations and proper usage procedures, engineers can minimize the risk of accidents, reduce workpiece damage, and maintain high operational efficiency. Safety considerations must be integrated into both equipment selection and daily operational protocols.

Balancing Safety and Performance

Permanent Magnetic Chucks provide an efficient and reliable means of securing ferromagnetic workpieces, but understanding their safety factors and overload protection mechanisms is critical for effective use. Design considerations, material properties, surface preparation, and operator practices all contribute to maintaining safe and stable operation. By respecting the rated capacities, adhering to recommended safety margins, and employing proper handling techniques, these devices can offer both strong performance and high safety standards in demanding industrial environments.