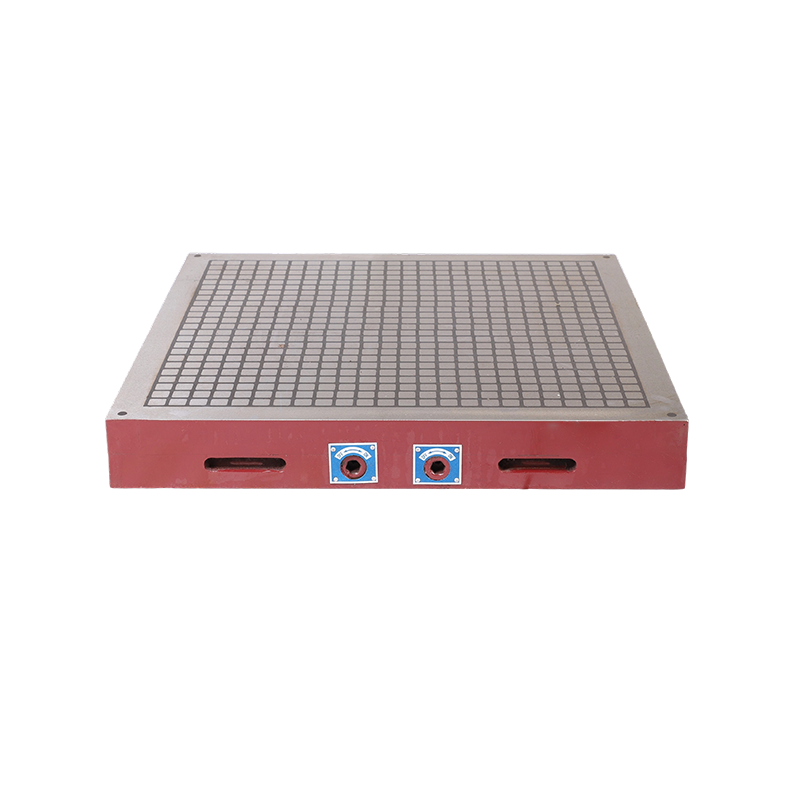

Permanent Magnetic Chucks are widely used in machining and metalworking applications to securely hold ferromagnetic workpieces without the need for clamps or external power. Their ability to generate a strong, stable magnetic field makes them highly efficient for grinding, milling, and other precision operations. While these devices are known for their reliability and ease of use, questions often arise regarding whether the magnetic field generated during operation can interfere with nearby electronic equipment or sensitive instrumentation. Understanding these potential interactions is crucial for ensuring safe and efficient workshop operations.

Nature of Magnetic Fields in Permanent Chucks

Permanent Magnetic Chucks generate a static magnetic field through the use of strong ferromagnetic materials embedded within the chuck. Unlike electromagnetic chucks, which require current to maintain their magnetic field, permanent designs maintain a constant field without external energy input. The magnetic field is primarily concentrated at the contact surface where the workpiece is held. While the field strength is sufficient to secure metal objects, it rapidly diminishes with distance, following the inverse square law. As a result, the magnetic influence is largely localized, though certain conditions may allow for minor field extensions beyond the immediate surface.

Interaction with Surrounding Electronic Equipment

Most modern electronic devices are designed with shielding to resist common levels of magnetic interference. Computers, CNC controllers, sensors, and measurement instruments typically operate without noticeable disruption when placed near a well-designed Permanent Magnetic Chuck. However, extremely sensitive equipment, such as precision magnetic sensors or certain medical devices, may register small disturbances if positioned unusually close to the chuck. The likelihood and severity of interference depend on factors such as the magnetic field strength, the distance from the chuck, the orientation of the electronic device relative to the field, and the presence of ferromagnetic components within the equipment itself.

Factors Mitigating Magnetic Interference

Several design and operational factors mitigate the potential for magnetic interference. The use of magnetic shunts, strategic placement of ferromagnetic shielding within the chuck, and proper positioning of sensitive equipment all reduce the likelihood of disruption. In addition, maintaining a reasonable distance between the chuck and nearby electronics ensures that the rapidly declining field does not impact their function. Most industrial setups naturally accommodate these considerations by separating heavy-duty machining equipment from sensitive electronics.

Practical Implications for Machining Environments

For most industrial environments, Permanent Magnetic Chucks can be used safely without concern for electromagnetic interference. Operators should still conduct site-specific assessments when placing particularly sensitive instruments near active chucks. Awareness of magnetic field zones and adherence to recommended clearances further minimizes risks. Incorporating basic shielding strategies, such as ferromagnetic barriers or enclosures for nearby electronics, can provide additional confidence in environments with mixed-use equipment.

Recommendations for Safe Usage

To minimize any potential impact on surrounding equipment, users should follow best practices such as positioning electronic devices at sufficient distances, keeping workpiece surfaces clean to maintain predictable magnetic fields, and regularly inspecting the chuck for damage or unintended field leakage. Educating personnel about magnetic field considerations ensures that both machining operations and electronic systems operate safely and efficiently within the same workspace.

Managing Magnetic Influence in Industrial Settings

Permanent Magnetic Chucks provide a highly effective solution for securing ferromagnetic workpieces, offering stable, energy-free clamping for a wide range of machining operations. While their magnetic fields are strong at the surface, they decline rapidly with distance, meaning that interference with nearby electronic equipment is generally minimal. Proper planning, appropriate shielding, and adherence to recommended clearances allow these devices to coexist with sensitive electronics, maintaining both operational efficiency and safety in modern machining environments.