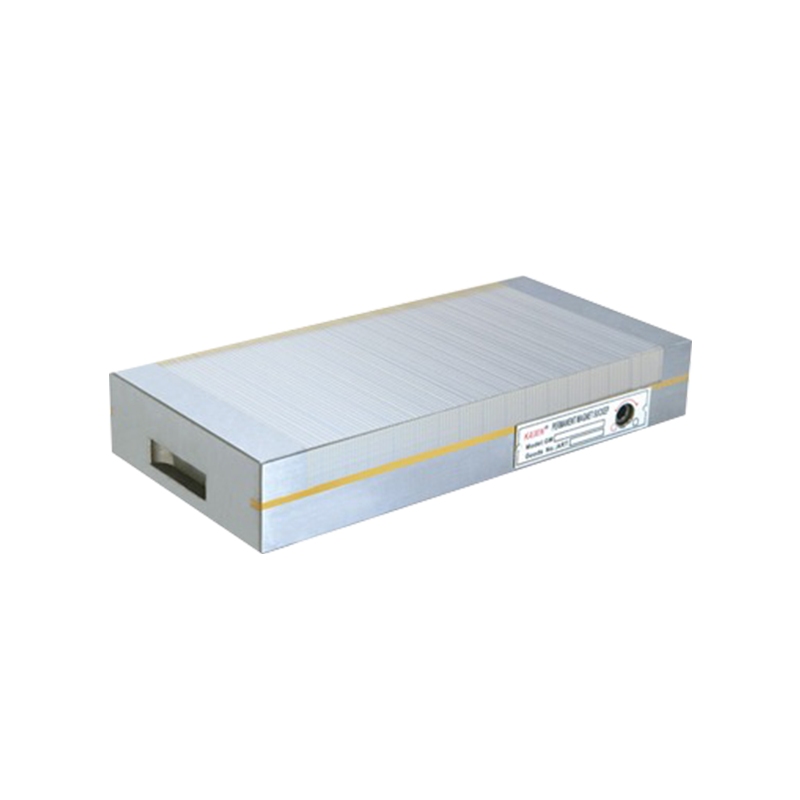

When assessing whether an Electro Permanent Magnetic Chuck can safely and effectively hold irregularly shaped workpieces, it’s essential to understand how its hybrid magnetic structure works and how it interacts with uneven surfaces. This type of chuck combines the reliability of permanent magnets with the controllability of an electromagnetic pulse, offering unique advantages compared with traditional chucks.

• Adapting to Surface Variations

Irregular workpieces often present gaps, uneven contact areas, or curved profiles. The magnetic flux generated by this type of chuck can partially compensate for these surface inconsistencies, allowing stable attraction when at least a portion of the workpiece makes proper contact.

• Maintaining Holding Force Without Power

Because magnetic retention continues even after power is removed, the workpiece remains secure during machining, reducing the risk of accidental demagnetization caused by power fluctuations.

• Limitation on Extremely Uneven Shapes

Workpieces with very small contact areas or extreme curvature may not achieve full magnetic penetration, resulting in reduced holding strength. In such cases, magnetic pole extensions or auxiliary clamping methods are sometimes required.

Thin workpieces introduce a different challenge: insufficient material thickness to support deep magnetic flux transfer. However, these chucks are designed with optimized magnetic circuits to improve performance.

• Low Distortion and Gentle Clamping

Traditional mechanical clamps can deform thin sheets. In contrast, magnetic clamping distributes force evenly, reducing bending or marking and preserving surface quality.

• Optimized Polarity Arrangement

Many modern chucks use close-pole or micro-pole structures that allow more concentrated magnetic fields, enabling effective attraction even for thin metal sheets that offer limited magnetic depth.

• Reduced Vibration During Machining

Thin materials can vibrate during high-speed cutting. Magnetic clamping reduces this risk by securing the entire surface rather than isolated points, improving precision and surface finish.

Not all metals react equally to magnetic attraction, so material compatibility must be considered.

• Ideal for Ferromagnetic Materials

Carbon steel, alloy steel, and tool steel achieve a strong holding force. The chuck’s magnetic field easily penetrates these materials, improving stability.

• Limited Effects on Non-Ferrous Metals

Aluminum, copper, and stainless steel grades with low magnetic permeability cannot be held magnetically. Auxiliary clamping systems are required for such cases.

• Effectiveness Depends on Surface Area

Even for compatible materials, the contact area between the workpiece and the chuck determines the final holding performance.

Several techniques enhance the holding performance when dealing with thin or irregular parts.

• Use of Pole Extensions

Adding magnetic pole risers or blocks increases effective contact area and adapts the chuck surface to curved or uneven workpieces.

• Cleaning the Contact Surface

Removing debris, rust, oil, or metal dust improves magnetic penetration and reduces slippage risk.

• Adjusting Chuck Mode or Section Activation

Many models allow activation of partial zones. Concentrating magnetism on smaller regions improves performance for small or delicate parts.

• Applying Support Fixtures

V-blocks, stops, or back supports help stabilize oddly shaped items during machining or grinding.

An Electro Permanent Magnetic Chuck generally performs well with thin and irregular workpieces when proper procedures are followed. Its ability to deliver uniform clamping force, maintain holding power without ongoing electricity, and adapt through modular accessories makes it suitable for many challenging machining applications. While extremely irregular shapes or non-ferromagnetic materials may require extra fixtures, the overall efficiency, safety, and precision benefits make it a reliable choice for modern workshops handling diverse workpiece geometries.