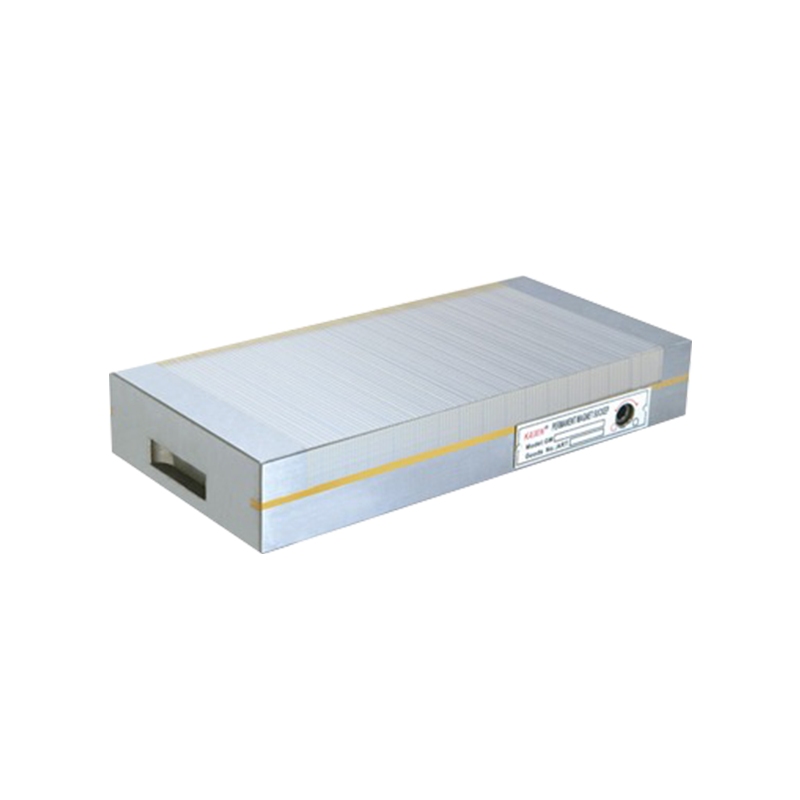

Reliable Holding with Grinding Magnetic Chuck

The Grinding Magnetic Chuck is an essential fixture in precision surface grinding applications. Designed to securely hold ferrous materials during machining, this chuck enhances accuracy and safety. By using magnetic force instead of mechanical clamping, it ensures an even and vibration-free grip across the entire workpiece. This uniform holding reduces distortion and allows for finer surface finishes, especially important in tool and die manufacturing. The Grinding Magnetic Chuck also speeds up setup time, as operators can place and remove workpieces more efficiently compared to traditional clamping methods. These chucks are available in permanent and electromagnetic versions, depending on the required force and frequency of use. Whether in manual or CNC grinding machines, they play a vital role in ensuring that materials remain stable under high-speed operation, causing more consistent and high-quality machining results.

Versatility and Rotation with Rotary Magnetic Chuck

For applications that demand angular or rotary movement during machining, the Rotary Magnetic Chuck offers a highly adaptable solution. This type of chuck allows continuous 360-degree rotation of the workpiece while maintaining a strong magnetic clamping force. It is widely used in circular grinding and indexing operations where parts need to be rotated for full-surface finishing. The Rotary Magnetic Chuck is designed to work seamlessly with lathes, rotary tables, and specialized grinders. Its ability to combine rotation with secure holding reduces repositioning and increases throughput in production environments. Operators appreciate the precision and repeatability it offers when dealing with complex geometries or curved surfaces. Many models also feature fine-pole structures to accommodate thinner workpieces without sacrificing holding power. As manufacturing processes increasingly incorporate multi-axis machining, the Rotary Magnetic Chuck becomes a key tool for improving productivity and machining efficiency.

Angle Accuracy with Magnetic Sine Chuck

For angle grinding and high-precision machining, the Magnetic Sine Chuck provides exceptional accuracy in holding parts at specific inclines. This specialized tool is built with precision-ground rollers and sine mechanisms that allow users to tilt the magnetic surface to exact angles using gauge blocks. It is particularly useful in toolmaking, mold work, and applications requiring chamfered or tapered surfaces. The Magnetic Sine Chuck combines the holding strength of magnetic technology with the mechanical advantage of sine geometry, allowing technicians to achieve exact angular positions without complicated fixtures. Most models include locking features to maintain rigidity during grinding operations, ensuring no slippage or misalignment occurs. This tool is especially valued in high-tolerance environments where even minor deviations can compromise part quality. With growing demand for intricate parts in aerospace, medical, and automotive sectors, the Magnetic Sine Chuck continues to be an indispensable solution for achieving good angular precision.

Enhancing Machining Through Magnetic Workholding

The evolution of magnetic workholding tools such as the Grinding Magnetic Chuck, Rotary Magnetic Chuck, and Magnetic Sine Chuck has significantly improved machining capabilities across industries. These tools provide reliable, quick, and accurate holding for complex operations without damaging the workpiece surface. They reduce the need for mechanical clamps, reduce operator intervention, and support a range of shapes and sizes. Magnetic chucks also contribute to better tool access, shorter cycle times, and overall process efficiency. As manufacturing technologies become more precise and automation-friendly, the role of magnetic chucks continues to expand. From flat-surface grinding to angular and rotary machining, these devices offer good flexibility, helping manufacturers maintain the high standards in metal processing and part fabrication. Their continued innovation ensures compatibility with modern CNC systems and makes them a smart investment for precision-driven workshops.