The Importance of Magnetic Lifting in Modern Industries

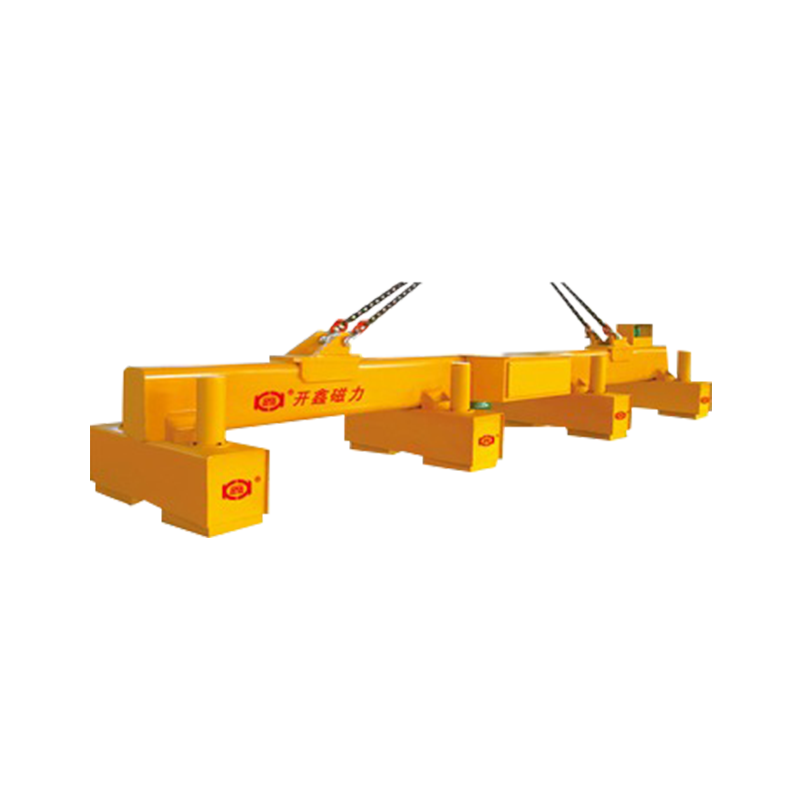

In many industrial sectors, moving heavy ferrous materials is a daily requirement that demands both safety and efficiency. Traditional methods such as chains, hooks, or slings can be time-consuming and potentially hazardous, especially when dealing with awkwardly shaped or delicate surfaces. This is where Heavy Duty Industrial Lifting Magnets have changed the process. These devices use powerful magnetic fields to securely grip metal objects without the need for additional fastening equipment. They have become invaluable in shipyards, steel mills, automotive plants, and large-scale construction sites where speed, safety, and precision are essential. The ability to lift large loads with manual intervention also reduces strain on workers and reduces the risk of workplace injuries.

Manual Control for Safety and Versatility

While fully automated lifting solutions are available, many operations benefit from the precision and control offered by Manually Switched Permanent Magnetic Lifters. These lifters use permanent magnets to maintain a strong grip on the load, and a manual lever is used to engage or disengage the magnetic force. This design means that once activated, they do not require electricity to maintain their hold, offering both energy savings and enhanced reliability in environments where power outages could be an issue. The manual control feature also gives operators confidence when positioning loads, as they can precisely determine when to secure or release a workpiece. This is particularly useful in manufacturing workshops where delicate adjustments are often necessary.

Durability and Cost Efficiency

One of the main reasons businesses invest in magnetic lifting technology is durability. Both Heavy Duty Industrial Lifting Magnets and Manually Switched Permanent Magnetic Lifters are engineered from high-quality materials designed to withstand challenging industrial conditions. Permanent magnets are resistant to demagnetization, ensuring consistent performance over many years. The devices have minimal moving parts, meaning maintenance is straightforward and downtime is reduced. Over time, the initial investment pays for itself by increasing productivity, reducing accidents, and lowering the operational costs associated with more complex lifting systems.

Applications Across Multiple Industries

Magnetic lifting solutions have a broad range of applications. In manufacturing plants, they streamline the transfer of metal sheets, plates, and components, accelerating production workflows. In construction, they make it easier to move structural steel elements into place with accuracy and stability. In shipbuilding, their strength allows workers to handle large steel panels safely, while their non-invasive grip reduces the risk of damaging surfaces. Even in recycling facilities, magnetic lifters speed up the handling of scrap metal, ensuring efficient sorting and transportation. This versatility makes them one of the practical lifting solutions in the industrial sector today.

Safety Advantages Over Traditional Methods

Safety is a primary concern in heavy lifting, and magnetic lifters address many of the risks found in traditional systems. Since they do not require slings or hooks, there is less risk of slipping or tangling. The consistent magnetic hold prevents sudden drops, and the release mechanism allows for smooth and controlled load placement. Additionally, because they do not damage the surface of the materials being lifted, they are ideal for use with finished or semi-finished products where surface integrity is important.

A Smart Investment for Industrial Operations

Incorporating advanced magnetic lifting devices into an industrial workflow is a decision that yields benefits in both efficiency and safety. Heavy Duty Industrial Lifting Magnets provide strength for large-scale operations, while Manually Switched Permanent Magnetic Lifters offer precision control and energy independence. Together, these tools represent a blend of power, reliability, and practicality that meets the diverse demands of modern industry. By reducing manual labor, improving safety, and ensuring long-term durability, they have proven themselves to be a smart and cost-effective investment for businesses.